Removing CO2 from the atmosphere is no longer optional, it is essential. Biogenic waste, abundant and underused, holds real potential when combined with engineering innovation. Converting biowaste into stable carbon through precise processes offers scalable, verifiable, cost-effective pathways to climate resilience. In this context, Helbling has supported the start-up Recoal. Helbling brings the engineering rigor and scale-up expertise to move faster from concept to certified credits, without compromising stability or cost.

Why Carbon Removal Is Now Essential

Global net-zero targets cannot be met through emissions reduction alone. Modeling aligned with pathways to the 1.5-degree Celsius target requires large-scale carbon removal. According to the UN Intergovernmental Panel on Climate Change (IPCC), this would require around 6 gigatons CO2 removal per year by 2050[1]. Prominent institutions estimate removal needs of 7 to 9 gigatons CO2 per year[2], with potential demand and supply gaps holding back climate progress.

Major removal strategies include:

- Nature‑based (e.g., afforestation) solutions

- Technology‑based (e.g., direct air capture, biochar) solutions

Effective solutions must ensure:

- Permanence – secure carbon stays out of the atmosphere for centuries or even longer

- Scalability – have the capacity for global expansion

- Verifiability – transparent, credible monitoring and certification must be ensured

Voluntary Carbon Market

The voluntary carbon market is evolving rapidly, with integrity standards and digital traceability gaining importance[3]. Prices for high‑quality removal credits now range from 100 to 500 US dollars per ton[4]. Market momentum underscores rising demand for durable emissions solutions[5].

Biowaste: A Powerful, Underutilized Carbon Feedstock

About one-third of global food production goes to waste, representing lost value and emissions liability. When this waste decomposes or is incinerated, CO2 or methane is released, directly undermining climate targets. Food waste is, however, rich in biogenic carbon. This offers a clear opportunity to offset these emissions by converting it into stable carbon forms such as biochar or hydrochar[6].

Recent research illustrates this potential, showing that converting food-waste digestate into biochar could save 93,000 tons of CO2 per year by 2030[7]. Yet food waste is only one part of the picture. A wide range of other biogenic residues can also serve as valuable feedstock for carbon removal. These include agricultural by-products such as crop residues, husks, and manures, together with forestry residues like sawdust, bark, and thinning materials, all contain significant carbon fractions. The organic fraction of municipal solid waste adds another resource stream.

At a global level, the production of biochar from agricultural and forestry residues alone could remove 3 gigatons CO2 annually, with broader estimates ranging from 0.3 to 4.9 gigatons CO2 per year depending on feedstock and scale[8]. Industrial side streams, including paper sludge and digestate from biogas plants, further extend this potential. Taken together, this diversity of sources demonstrates that biowaste is not a narrow or niche input but rather a broadly available and underutilized resource for durable carbon storage.

Turning Potential into Practice: Engineering Challenges

Thermochemical techniques, such as vapothermal carbonization (VTC), hydrothermal carbonization (HTC), and pyrolysis, offer routes to converting food waste into solid, carbon-rich products. Key engineering parameters include temperature, pressure, residence time, and yield-versus-stability trade-offs. Regulatory alignment, energy inputs, and throughput targets further shape technical feasibility.

How Helbling Supports Carbon Removal Innovations

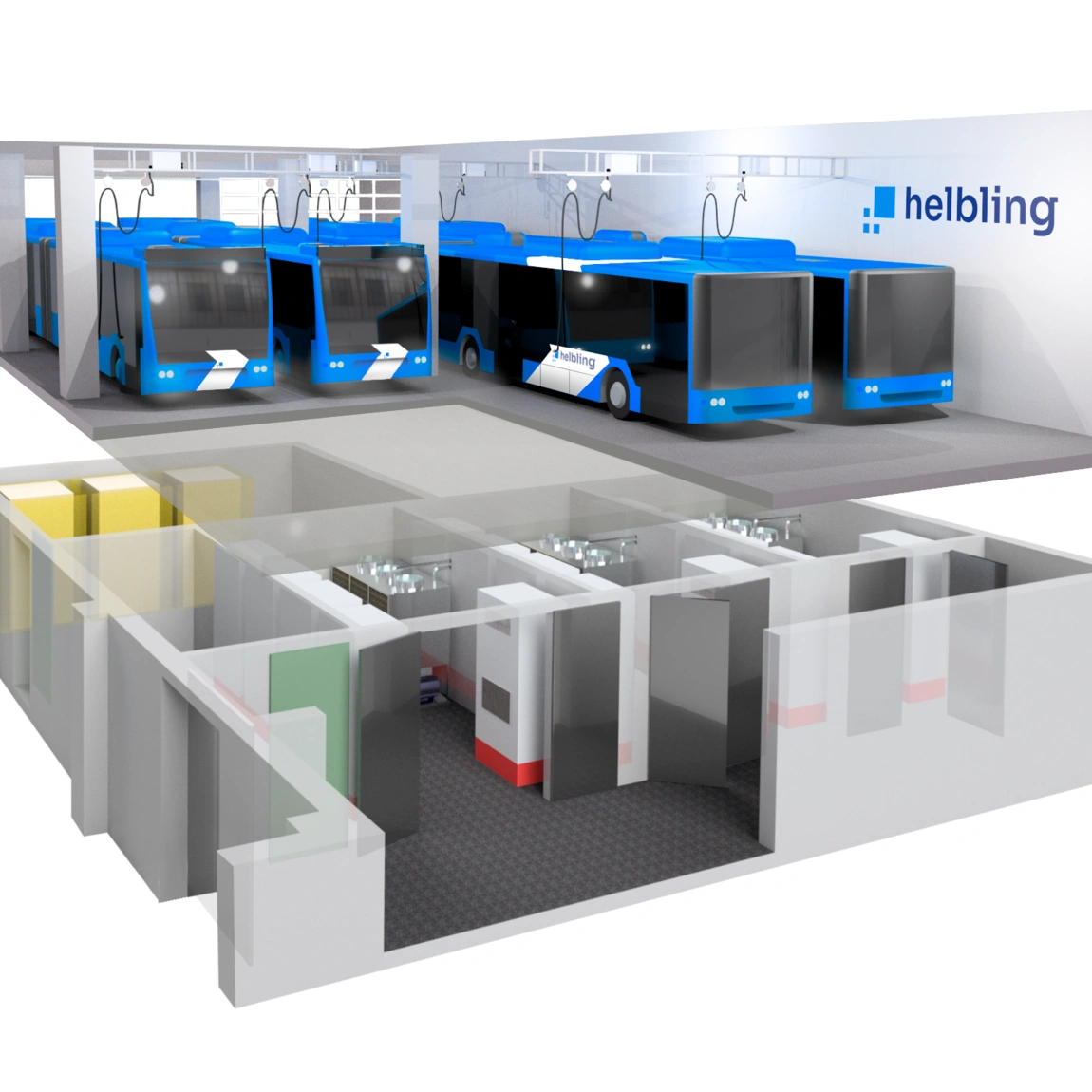

Helbling’s role is focused on enabling companies to move from concept to impact. Drawing on experience from process industries, energy systems, and product development, we support clients with targeted services that turn carbon removal ideas into scalable solutions.

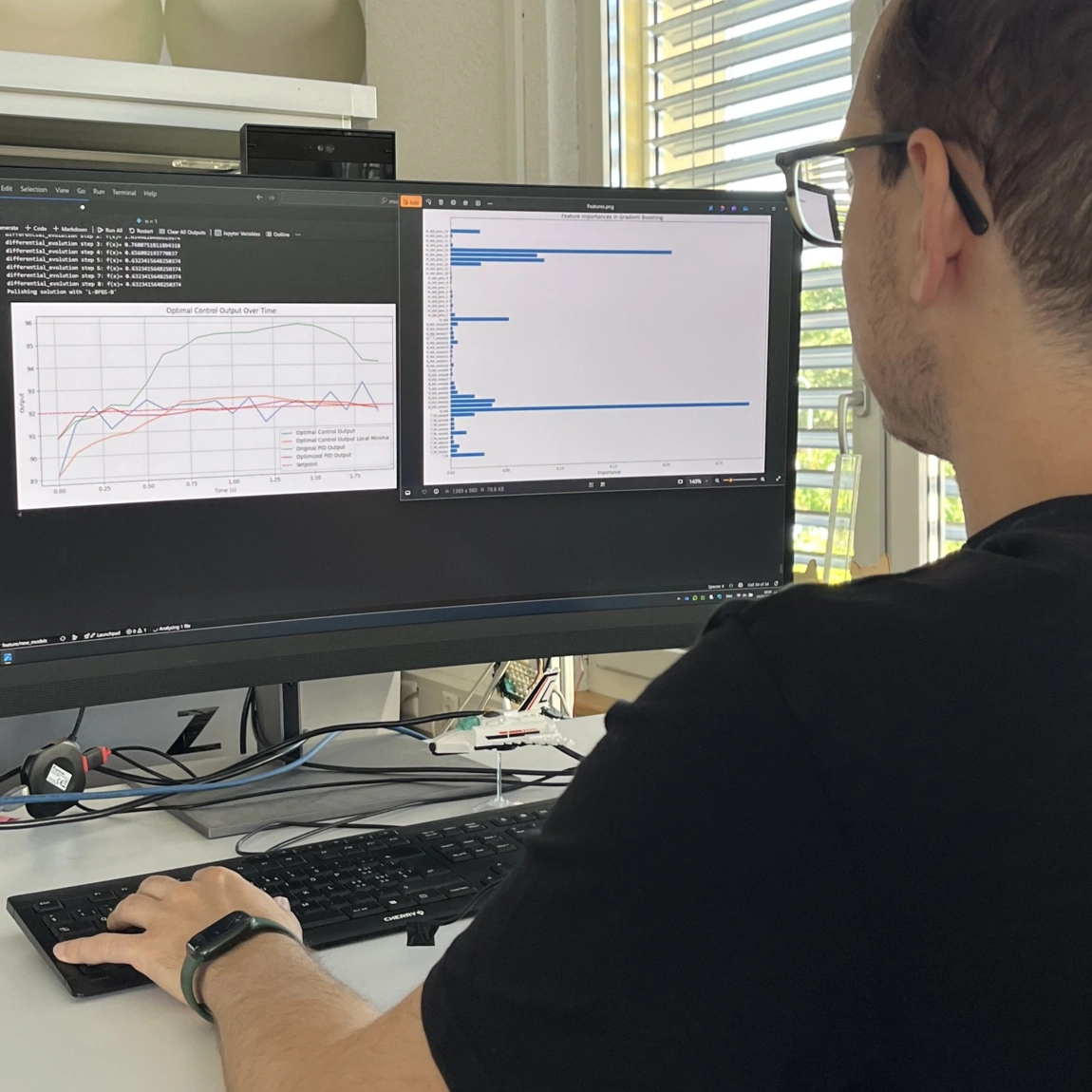

- Process modeling and optimization: Helbling’s chemical and process engineers can use advanced simulation environments and flow modeling tools to analyze thermochemical pathways. Their work defines the operating windows that maximize carbon stability while minimizing energy demand.

- Material and system engineering: Mechanical engineers, material scientists, and environmental specialists design and validate equipment such as reactors, heat exchangers, and handling systems. Experience from industrial plant projects ensures robustness even with highly variable biowaste streams.

- Techno-economic evaluation: Interdisciplinary teams combine engineering know-how with cost modeling, lifecycle assessment, and certification expertise. This offers a clear view of trade-offs, risks, and regulatory requirements, ensuring pathways are not only technically feasible but also commercially and environmentally viable.

- Pilot plant and scaling: Helbling applies its track record in plant engineering, automation, and prototyping to move concepts into real operation. Dedicated test facilities, measurement systems, and scale-up methodologies enable validation under industrial conditions and preparation for deployment at commercial scale.

At the core of all this is Helbling’s interdisciplinarity: Our expertise and experience in the areas of processes, simulations, materials, and project management contribute to ensuring the development of reliable solutions that are ready for market.

Case in point: Helbling has supported the Swiss start-up Recoal. Through targeted process refinement and interdisciplinary engineering support, both stability and hydrochar yield were improved, paving the way for pilot plant deployment. To this end, analytical know-how was combined with practical engineering experience, ensuring that the process not only performed better in the lab but was also prepared for the transition toward larger-scale feasibility. This collaboration illustrates how Helbling helps innovators to reduce technical risks at an early stage and how a reliable foundation for scaling up carbon removal technologies can be created.

Looking Ahead: A Circular, Measurable Future

Carbon removal is an increasingly regulated practice; certification frameworks, both of a voluntary nature and those at EU level, are now rapidly emerging. Engineering excellence coupled with transparent measurement processes are essential for trust and impact. Biowaste-based removal merges circular economy principles with climate action.

Summary: Engineering excellence enables lasting, scalable, and verifiable CO2 solutions

Biowaste is often treated as a liability, yet it holds untapped potential for engineered carbon removal. By stabilizing carbon that would otherwise escape as CO2 or methane, advanced thermochemical processes transform unstable organic matter into durable storage. This approach bridges climate targets with practical innovation: it addresses permanence, scalability, and verifiability while creating pathways for emerging carbon markets. Engineering precision – balancing process parameters, considering regulatory requirements and ensuring stability - turns a waste problem into a climate protection solution. Collaborative, system-oriented solutions have the capacity to unlock scalable, verifiable carbon removal approaches, and Helbling helps to realize these by combining interdisciplinary engineering competence with proven tools for development and scale-up.

Authors: Akanksha Jain, Roland Lehmann, Armin Picenoni

Main Image: Salah Ait Mokhtar via Unsplash

References:

[3] (Carbonmark, ipcc.ch, Green Finance Institute, wsj.com)