Industries

Technologies

Exoskeletons are now widespread in industrial settings, but they can also help to greatly simplify life for people living with disabilities. Helbling leveraged its expertise in this field to develop a prototype in collaboration with the HackaHealth initiative that can serve as a blueprint to transform the lives of future patients.

Development of a personalized exoskeleton

Personalized assistive technologies are transforming the lives of people with disabilities, offering new levels of autonomy and mobility. With rapid advancements in both MedTech and industrial sectors such as robotics and AI, the potential of these solutions continues to grow. Building on extensive experience in these fields, Helbling has built a functional prototype to be tested by a patient affected by long-term consequences of polio. This prototype demonstrates a core concept that can be adapted to support the mobility of patients with upper-limb-related challenges. To this end, Helbling partnered with the Swiss initiative HackaHealth, a community dedicated to supporting people with disabilities by developing personalized solutions to improve their day-to-day lives.

Demand for assistive exoskeleton technologies on the rise

The growing demand for assistive exoskeletons is being driven by global demographic and healthcare challenges, most notably an aging population with a rising prevalence of mobility impairments, and an overloaded healthcare system. Exoskeleton technology has the potential to ease the burden on caregivers and healthcare systems by facilitating and improving rehabilitation and increasing patient autonomy.

In industrial environments, exoeskeletons can be used to prevent workplace injuries, reduce fatigue, and improve worker productivity. Technological advances in robotics, wearable sensors, artificial intelligence, and lightweight, durable materials are making exoskeletons more practical, affordable, and accessible.

Consequently, this has propelled the global market into a rapid growth phase where the exoskeleton market is expected to grow from USD 0.56 billion in 2025 to USD 2.03 billion by 2030. This growth is primarily attributed to the rising societal need and the immense potential of assistive exoskeletons to transform rehabilitation, mobility, and human performance worldwide [1].

More than twenty years of MedTech, industrial, and robotics experience ensure that Helbling has the interdisciplinary base required to develop next-generation exoskeletons.

A design thinking approach for a personalized assistive arm support

Helbling partnered with HackaHealth to turn challenging idea into reality. In a pro-bono collaboration with HackaHealth, Helbling adopted one of the Hackathon projects aimed at helping a patient with an arm disability to develop an assistive device to enhance her independence at home.

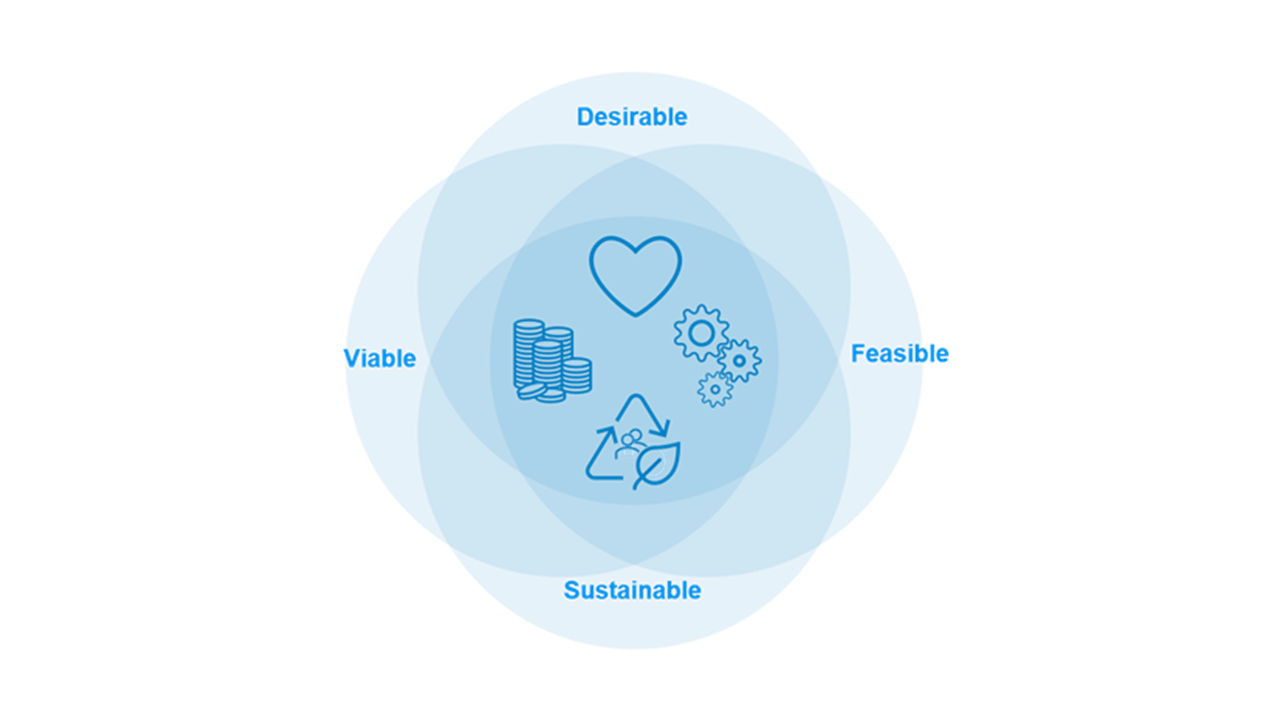

A design thinking approach was implemented to ensure that the solution was meaningful for the patient, technically achievable, and easily maintained by HackaHealth. The aim of this method is to address four main factors: desirability, viability, feasibility and sustainability.

Personalization: Getting to know the specific needs

The patient, who contracted polio at the age of two, has limited mobility in her shoulders and upper arms but maintains functionality in her forearm and right hand. Understanding her individual needs was essential to ensuring both feasibility and desirability, and the team invested in detailed observation and dialogue to identify real pain points in daily activities. Reduced strength, limited range of motion, short torso length, and balance considerations formed the basis of the biomechanical and ergonomic design requirements. The solution needed to enable the patient to independently wear the device, move safely without compromising stability, and lift her arm up to approximately 130° while holding an object of around 1.5 kilograms, tasks she could not perform on her own.

Realization: Development process prioritizes ease-of-use, maintenance, and reproducibility

To support viability, the functional prototype must be built using off-the-shelf or low-cost components wherever possible to facilitate maintenance and future upgrades of the prototype by HackaHealth, and to ensure that the device could be realistically produced or adapted beyond the prototype stage at a later date. Usability, serviceability, and cost-efficiency were therefore built into the architecture from the start. The parts of the design that needed to be personalized for this patient used rapid prototyping techniques to lower costs. The idea was to develop modules that can be personalized and adapted to each patient (e.g. belt and position of the shoulder joint), and standard modules that could be re-used for other patients without adaptation (e.g. actuator unit and electronics box).

From an engineering standpoint, the focus shifted to feasibility, determining how to transform the concept into functioning hardware. With minimal residual strength in the upper body, the system required an actuation mechanism that could transfer the load of arm movement to the hips. As a solution, a custom thermoformed waist belt was developed using a 3D scan of the patient’s torso to distribute the weight as evenly as possible without compromising balance. The control interface was adapted to the limited dexterity of her other hand and allows intuitive control.

The overall system weight, including battery, was kept under 1.5 kg by optimizing power consumption and incorporating a self-locking mechanism. Another challenge related to the difficulty of maintaining balance while putting on and taking off the device. To make this process easier, a custom chair was built with a magnetic interface to the belt that can anchor the device while securing it around the waist without compromising the patient’s safety. Additionally, other safety features to limit the maximum torque and current under single fault conditions were implemented.

Throughout development, multiple prototypes were evaluated through iterative testing sessions with the patient. Each iteration improved comfort, alignment, range of motion, and energy efficiency. This iterative cycle enabled continuous refinement based on real feedback rather than theoretical assumptions. In a final test the patient was able to independently set up, wear the device and perform common tasks that were previously impossible, demonstrating the success of user-centered engineering.

Sustainability: Putting innovation at the service of society

Finally, sustainability also shaped the broader purpose of the project, extending beyond technical considerations to the idea of giving something back to society. By supporting HackaHealth, Helbling made its engineering expertise available to people that cannot profit from standardized assistive solutions. Personalized devices like this provide them with an opportunity to regain autonomy and participate more fully in daily life. In this sense, sustainability is reflected in the long-term social value created by making meaningful technology accessible to those who need it most.

For Helbling, this project provided valuable learnings and a demonstrator to publicly showcase technical competences in the field of assistive technology.

Summary: Innovations such as exoskeletons can greatly assist people with disabilities

Helbling sees significant potential in this field and, through this project, has identified several opportunities to further enhance the functionality and usability of the prototype. These include the integration of advanced closed-loop control systems based on voice commands, EMG signals, or brain–computer interfaces (BCIs), enabling both assistive and rehabilitative applications. We would invite anybody interested in collaborating on this or similar projects to get in touch. Together, by leveraging innovative technologies, we can significantly improve the quality of life for people living with disabilities.

Authors: Noaf Alwahab , Laura Santos Carreras

Main Image: Helbling

[1] Exoskeleton Market Size, Share & Trends, 2025 To 2030. Retrieved from https://www.marketsandmarkets.com/Market-Reports/exoskeleton-market-40697797.html