Whether in a coffee machine or a diagnostic device, thick film heating systems quickly and precisely bring liquids up to temperature in an energy-efficient manner. Helbling pursues a holistic approach to the development process, optimally tailoring thermal performance, control logic and safety functions to the individual application.

Holistic system design coordinated from the outset

Instantaneous water heaters are used to make an espresso in a matter of seconds or to ensure a sterile fluid supply in hospitals – essentially, wherever liquids need to be heated quickly, precisely and in a space-saving manner. To achieve this, the liquids are passed through channels within heating elements.

The system design is crucial to this. Helbling experts boast long-standing development experience and pursue a holistic approach to design. In this way, the instantaneous water heaters combine heating elements, sensors and controls as part of an optimally coordinated system. The printed, low-mass heating elements ensure ultra-fast, uniform heating – with virtually no waiting time. Thanks to demand-driven heating, there are no standby losses, which significantly increases energy efficiency.

Typical sensors such as temperature sensors, flow meters, pressure or safety sensors are intelligently embedded in the system and enable precise control. This is complemented by specially developed electronics and firmware that interact perfectly with the other components.

In this way, customers benefit from a fully integrated heating system from day one – tested, calibrated and ready for use.

Focus on sustainable products with a future

The heating solutions developed in this way meet the highest requirements in terms of energy efficiency and safety. They support eco-design specifications and help to reduce the ecological footprint of the devices – without compromising on performance.

High-end innovation through interdisciplinary teams

In such cases, Helbling's teams combine expertise in mechanics, electronics, software and physics. This close collaboration ensures that all system components – from material selection and heating patterns to sensor positioning – are perfectly coordinated.

Adaptive control algorithms continuously adjust power and flow to real-time data. As such, simpler, more cost-effective heating elements can often be used without impairing system performance. This not only reduces the development time, but also serves to cut overall costs, while maximum stability is ensured at the same time.

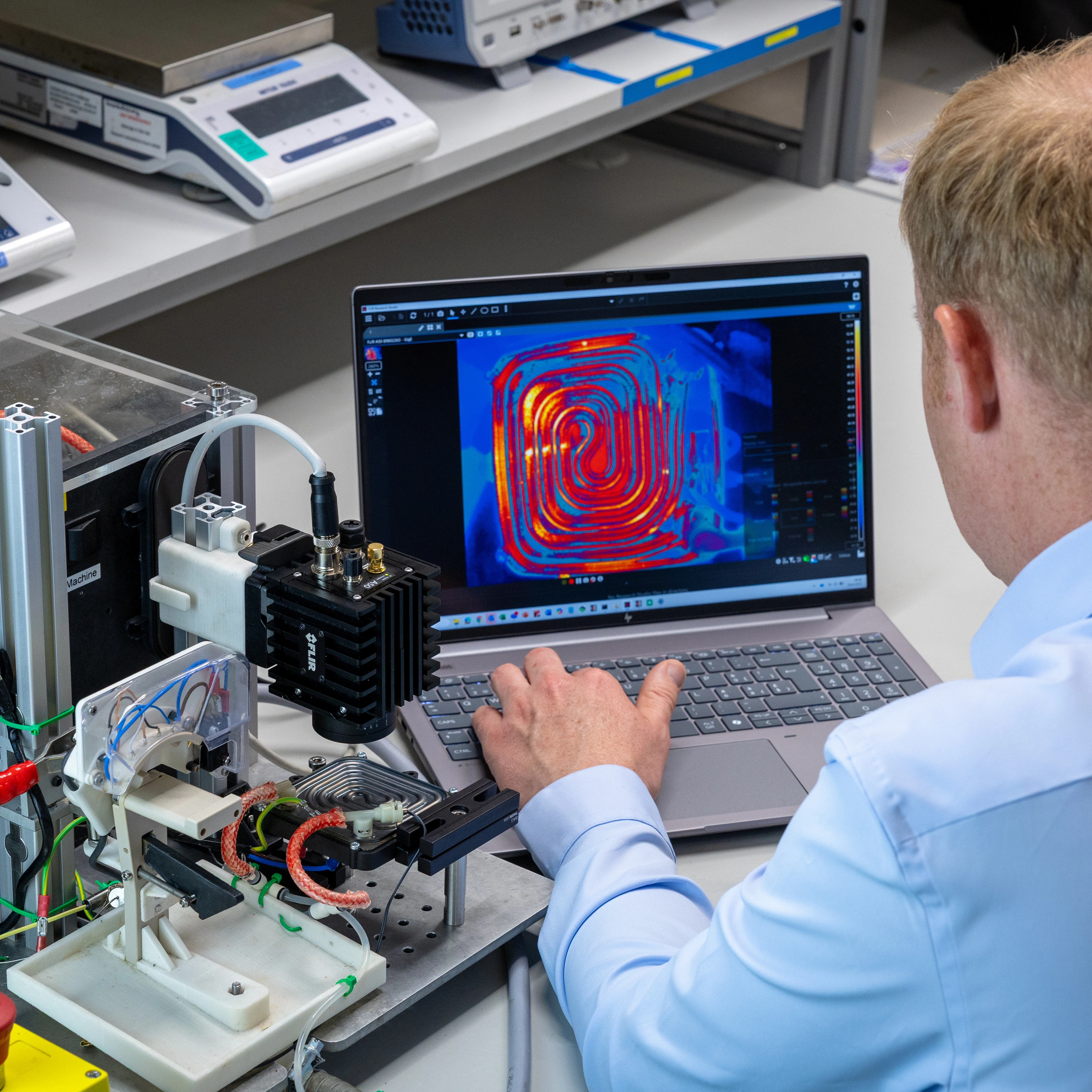

Faster to market – thanks to simulation

Helbling uses digital twins and software-in-the-loop testing as early as the concept phase to virtually validate heating modules and controls. This allows designs to be optimised before any hardware is built. In this way, materials are saved and test cycles are reduced, in addition to avoiding nasty surprises further down the line.

As a result, many of the projects already meet the specifications with the first real prototype – with a shorter development cycle and significantly lower risk.

Summary: Helbling combines maximum performance with efficiency in heating systems

With its system design approach, Helbling accelerates the development cycle, minimizing costs and the risk of delays in the process. This ultimately results in reliable, efficient and cost-effective heating solutions that are perfectly tailored to the respective application.

Author: Rainer Maisch

Main Image: Helbling