Technologies

August 2021

Diffractive optical elements (DOEs) offer unique possibilities that are not able to be achieved with other optical elements. Designing them properly is complex; Helbling supports its partners with its know-how and experience in this field.

What are diffractive optical elements?

At the USA – Russia summit in Switzerland in June 2021, US President Joe Biden received a fascinating gift from Switzerland: a glass plate that projects an image when illuminated. The technique used here is caustic, a refractive method. The same effect can also be created by diffraction, a technique that has unique properties and therefore provides a basis for new product innovations.

Even though the diffraction effect is known for more than 300 years, DOEs have only started to be used more widely in the last few years. Today, the applications range from security features on banknotes to beam shapers for laser welding and multifocal microscopy lenses, to name just a few. DOEs are very attractive because they can create light patterns of almost any shape from a simple laser beam while being flat and thin plus offering high efficiency.

DOEs shape light

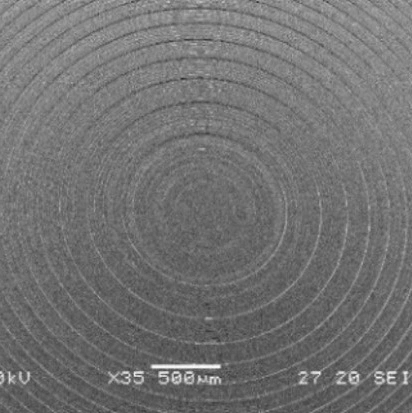

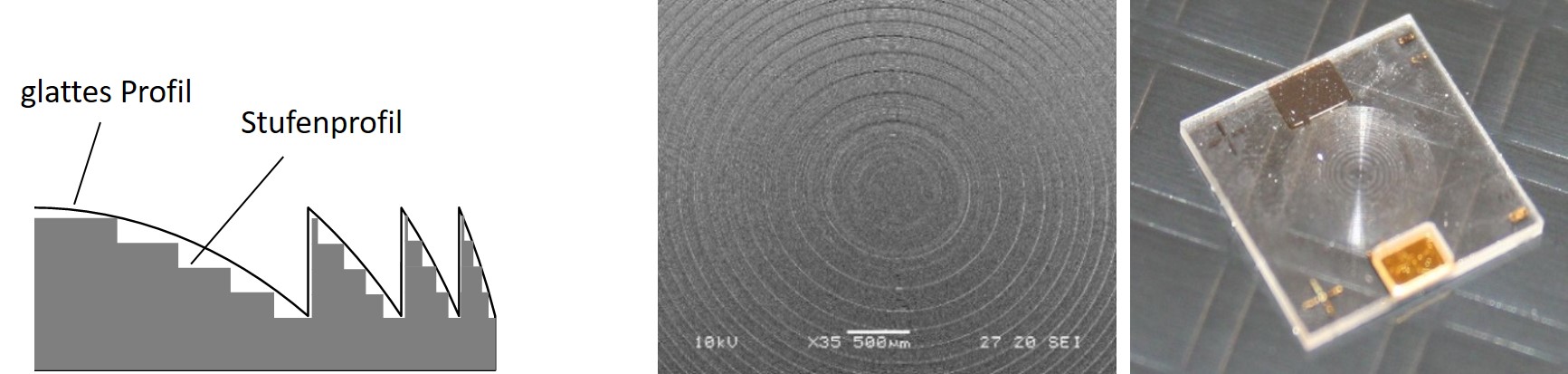

DOEs are usually made as thin plates with microstructures on the surface that cause diffraction effects. These structures can have smooth or step profiles, which define the light pattern behind the DOE.

New fabrication technologies developed in recent years have made DOEs commercially viable even for price-sensitive applications. Today they can be produced in large volumes at a low cost, making them an interesting option for smartphones, sensors for autonomous vehicles, or vision care products.

DOEs in artificial intraocular lenses improve vision

The versatility of DOEs sparks the creation of innovative products. For example, an active intraocular lens containing a DOE was developed in a collaboration between Helbling and Elenza, an innovative American medtech start-up. Artificial intraocular lenses are used to treat cataracts. In most cases, monofocal lenses are used, which only enable the patient to see sharp images at one distance and still require a pair of glasses to see at the other distance. Combining a DOE with a liquid crystal cell allows the optical power to be switched automatically simulate the natural accommodative ability of the lens of the eye.

The DOE design needs to match its application

Understanding the requirements of your application and how they affect the DOE design is critical for successful product development. Important aspects to consider include target cost per device, production volume, required quality, and the operating environment. The characteristics of the light source (wavelength, optical power, etc.) also play a major role in the DOE design. These various aspects inform the selection of the DOE material (glass, plastic, etc.), the fabrication technology (photolithography, injection molding, etc.), and the optical design (step profile, smooth profile, element thickness, etc.). As a neutral partner, Helbling can evaluate the different options independently and select the most suitable material and fabrication process.

Optical modeling of DOEs – selecting the right tool is key

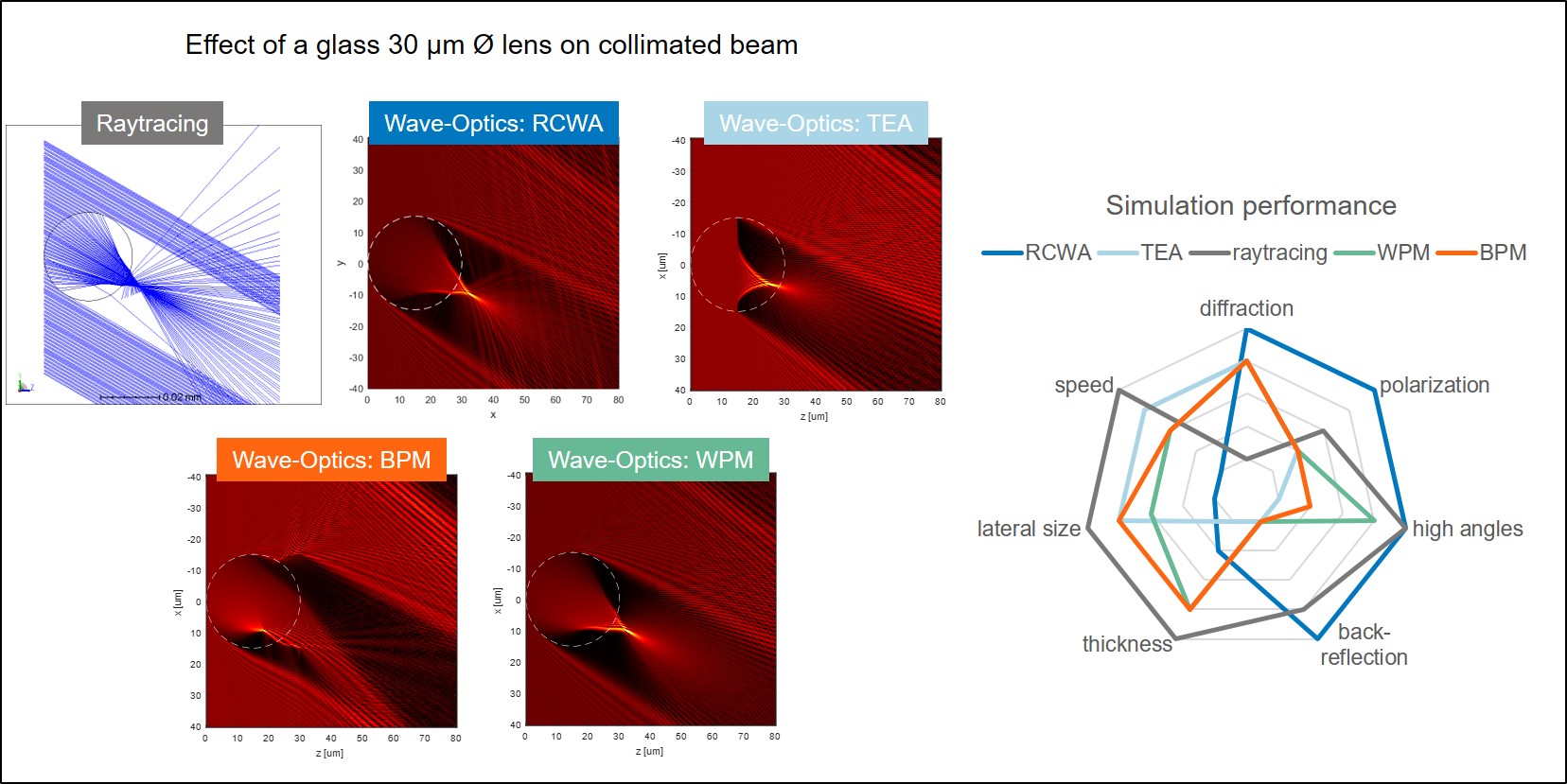

Computer models that simulate light patterns are used to determine the required microstructures for a DOE. But modeling DOEs is difficult due to their large number of microstructures distributed over their macroscopic size. Ray tracing, the most commonly used tool for refractive optics, does not take diffraction effects into account. Simulating wave propagations fully from each microstructure over the entire DOE requires a huge amount of computational power. Therefore, suitable modeling methods for DOEs rely on making simplified assumptions.

The method with the fewest assumptions is the rigorous coupled-wave analysis method (RCWA). It treats light solely as an electromagnetic wave and only assumes a periodic structure. This method is limited to small elements due to the required computational power.

Thin-element approximation (TEA) is very frequently used since it enables fast simulation with low memory requirements. This method assumes that the light only changes its phase while passing through the DOE but not its direction. It works well for thin DOEs and small light angles but gives faulty results in other cases.

Beam propagation methods (BPM) and wave propagation methods (WPM) are based on more complex simplifications. They are more suitable than TEA for thick DOEs and large light angles but need significantly more computational power.

Understanding the advantages and limitations of each method is difficult but critical for selecting the right modeling tool. Helbling has developed a series of proprietary modeling tools to simulate and optimize DOE designs for a wide range of applications.

Conclusion: know-how is key for innovation with DOEs

DOEs are powerful optical elements offering possibilities that are not able to be achieved with any other refractive optical element. But their proper use and implementation needs to be carefully considered, and the fabrication method needs to match the requirements of the application. Helbling can provide support with know-how in the field of refractive and diffractive optics, optical design capabilities, and experience in product development.

Author: Helen Wächter Fischer