Technology

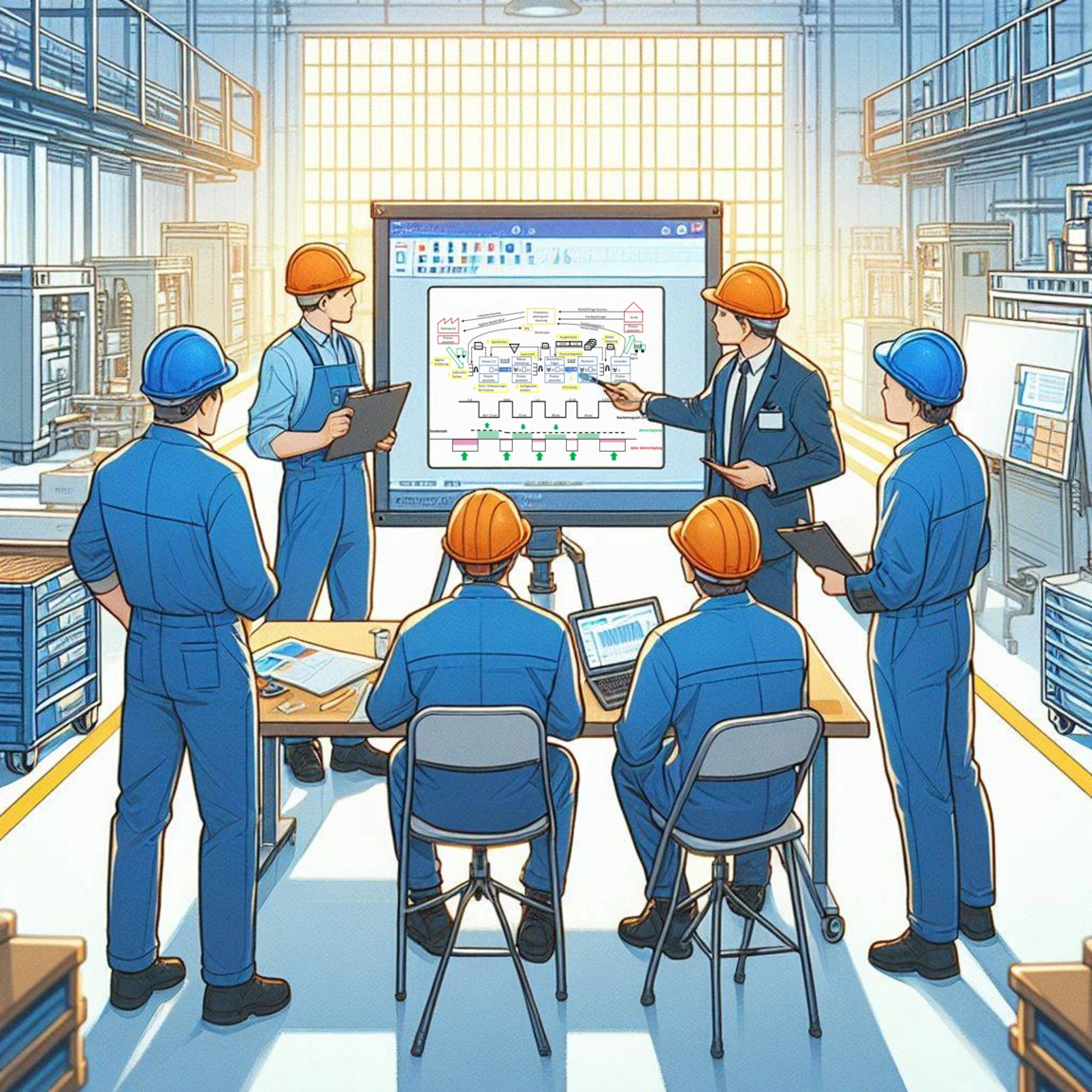

Factory Planning & Operations Engineering

As an independent partner, we support you in all phases of factory planning & operations engineering. From the development of innovative production concepts, and the optimization of existing systems to the verification of economic efficiency.

Your challenges

Whether you are a production company, logistics firm or maintenance provider - as a flexible and versatile service provider, we support you in all planning matters relating to your business and beyond.

- Feasibility studies

- Factory / facility layouts and site structure

- Planning in a BIM environment

- Interface coordination

- Investment and operating cost calculations

- 2nd opinion (external view)

- Technical / operational due diligence

- Green/brownfield projects

- Site location selection

- Project management

We systematically guide you through all phases of the factory planning process, from the definition of the requirements to the support during realization. This way, we guarantee the best possible result in terms of quality of implementation, risk minimization, on-time delivery and target costs.

As a flexible partner, we adapt our approach to the individual situation and your needs.

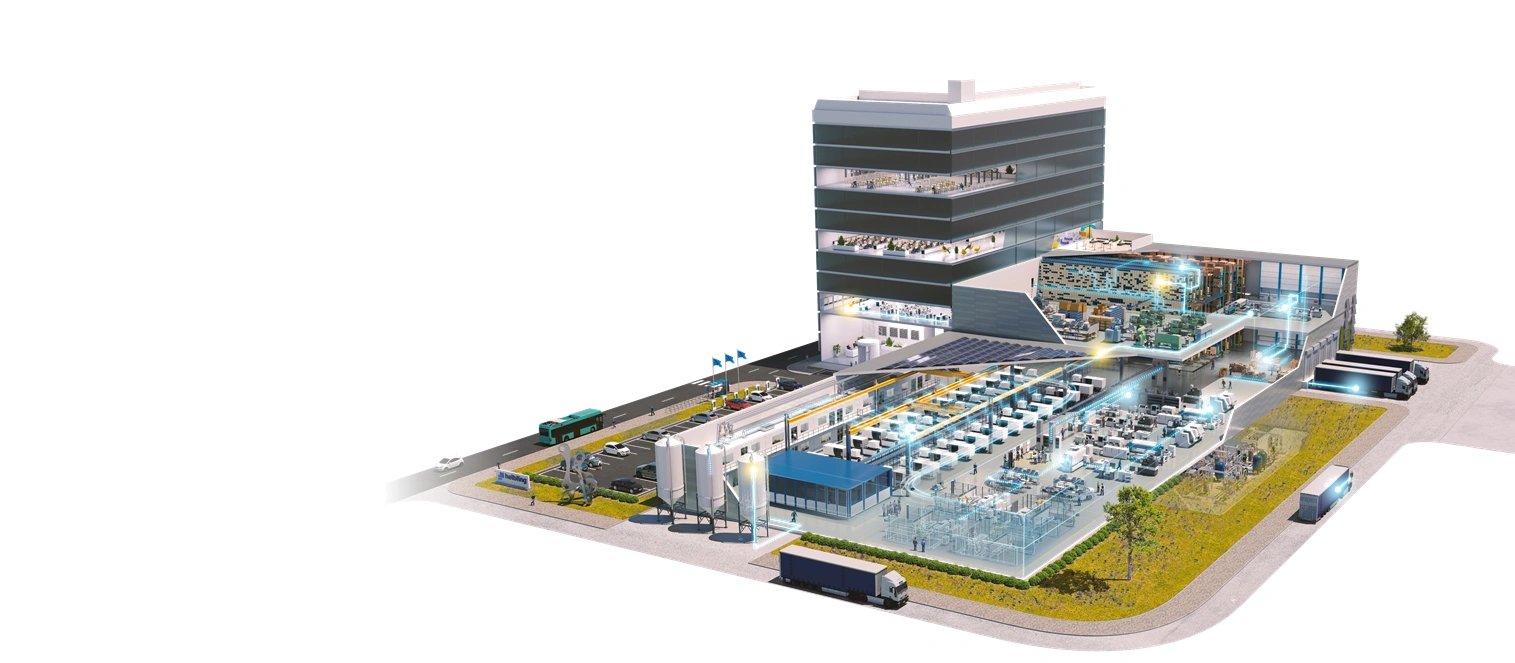

Production

For maximum productivity, we plan "from the inside out" and ensure well thought-out and efficient production.

Logistics

As an independent partner, we support you in selecting and planning the optimum (intra)logistics solution, making a significant contribution to your profitability.

Process design an optimization

Right from the start, we approach layout and operating processes as an inseparable unit to achieve holistic optimization.

Digital twin / material flow simulation

Based on a cost-benefit analysis, we support you in setting up, introducing and maintaining a digital twin in order to optimize processes and minimize risks in complex production systems.

Sustainability

For a liveable future, we develop effective solutions for the environment, economy and society. With our holistic approach, we support you in implementing your sustainability goals, from the product, machine and production line to the complete factory.