Technologies

Solid tires are becoming increasingly important for autonomous logistics solutions. They are durable, require minimal maintenance, and offer significant environmental benefits. These characteristics ensure that autonomous vehicles can be operated reliably and efficiently to meet the high demands of modern logistics. However, at speeds above 20 km/h, efficient cooling during the operation of solid tires is crucial. Helbling develops predictive system models that simulate the thermal behavior of the tires. This enables the cooling solution to be sized appropriately, ensuring worry-free operation during extended or high-speed use.

Solid tires differ fundamentally from conventional tires due to their solid rubber or polymer structure without an inner air-filled chamber. This design eliminates the risk of tire punctures and increases durability, making them the ideal solution for industrial transport vehicles and autonomous logistics systems. They are used for applications including forklifts and warehouse vehicles, transporting heavy loads using industrial vehicles, construction machinery, earth-moving equipment, and road construction. Understanding the thermal behavior of these tires is crucial for optimizing their performance and ensuring the safety and efficiency of autonomous transport vehicles, especially at higher speeds. Effective heat management during operation prevents potential failures and premature material degradation.

This is the only way to fully leverage the benefits of solid rubber tires: safety, high performance, extended lifespan, lower maintenance costs, and ecological sustainability.

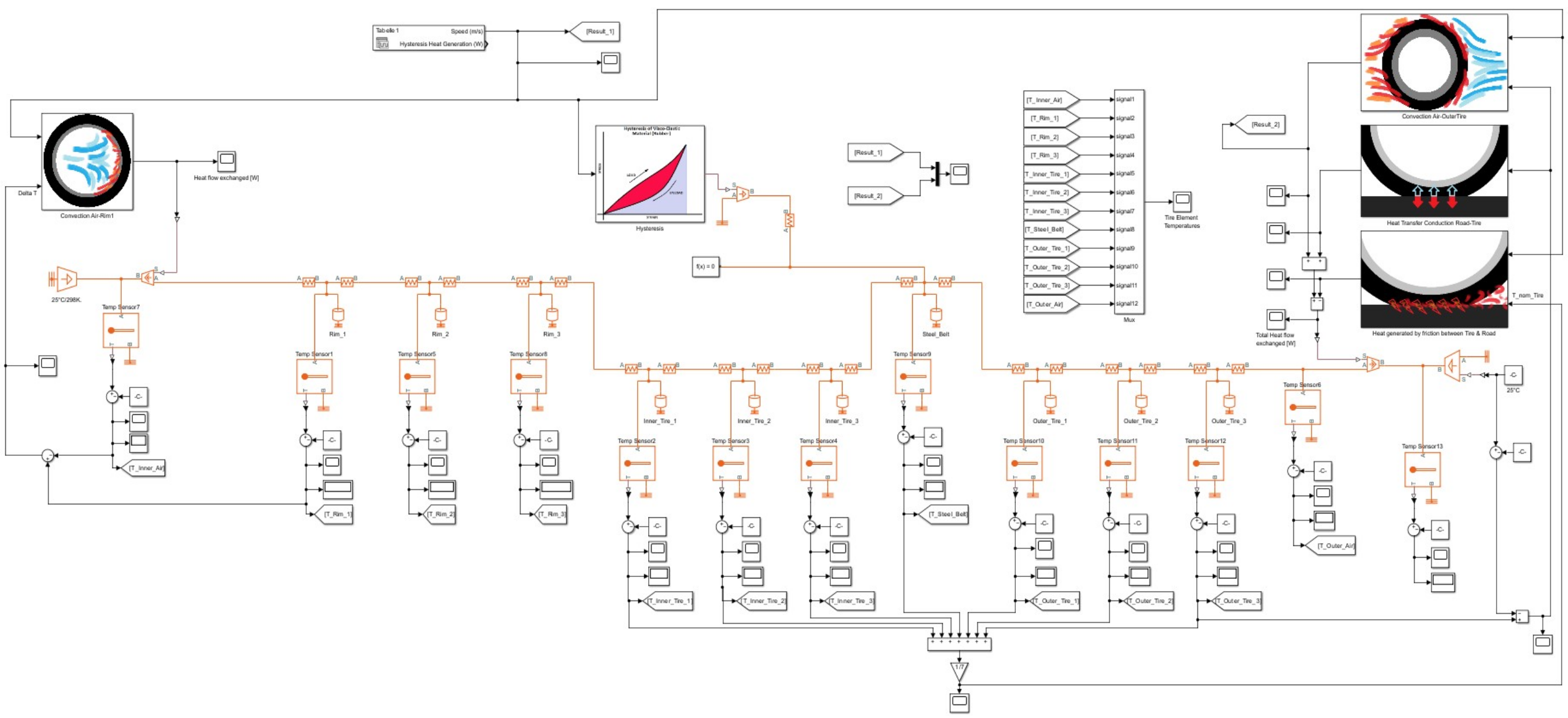

Helbling has gained experience on a project basis in the thermal management of solid rubber tires. Predictive system models that describe the thermal behavior of the tires during operation are fundamental. This approach requires mathematical and physical knowledge as well as expertise in the longitudinal and lateral dynamics of vehicles and fluid dynamics. This demonstrates the interdisciplinary nature of such projects. Helbling can draw on specialists from the fields of vehicle technology, modeling and simulation, and thermal and fluid management.

The thermal model forms the basis of the simulation

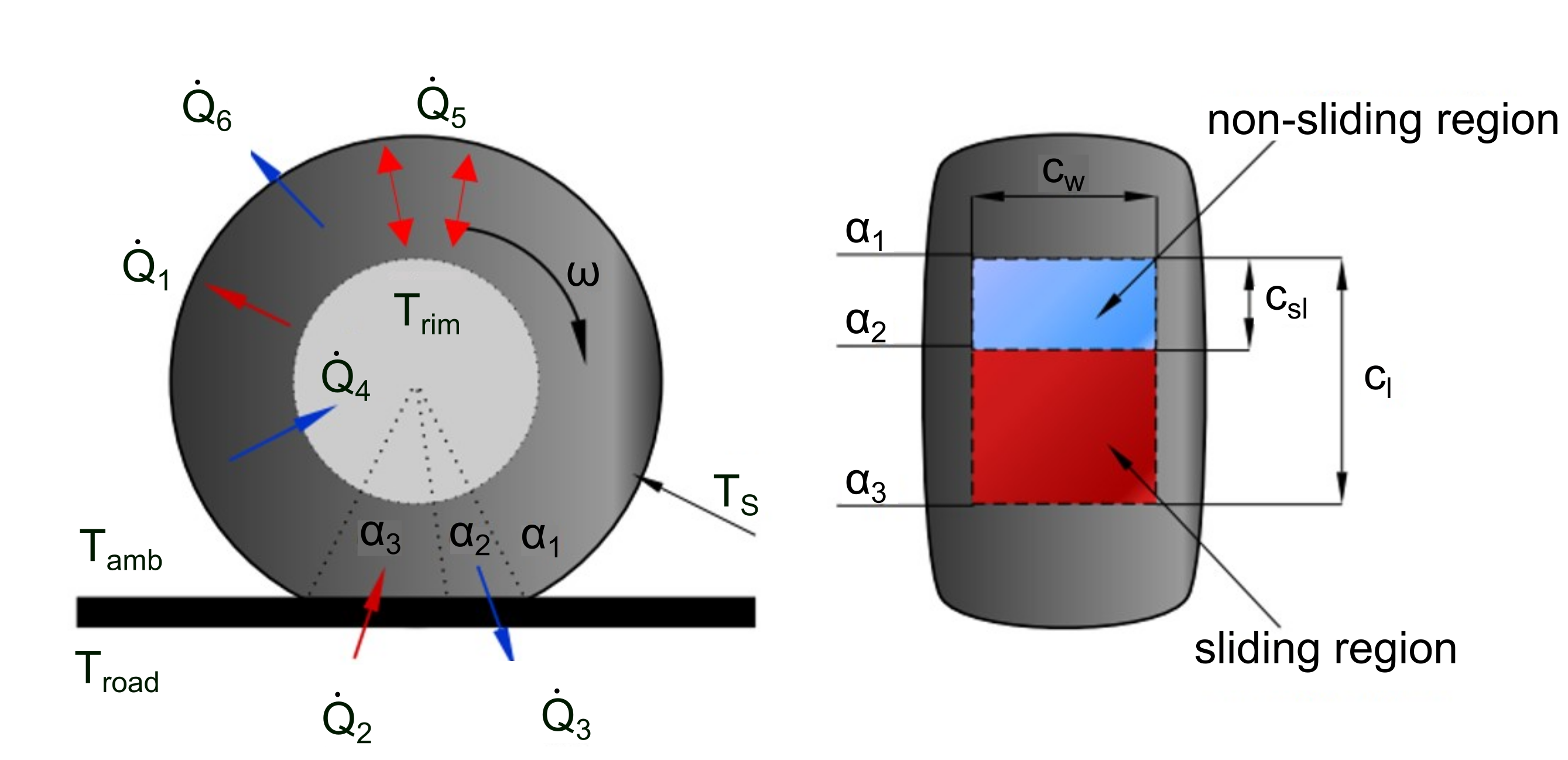

The thermal behavior within a solid tire results from various phenomena during driving or braking phases. By using mathematical and physical formulas, a predictive system model can be developed to simulate this thermal behavior. The model requires detailed technical data, such as thermal conductivity, conductive and convective heat transfer coefficients, and heat capacity. These parameters are often well-protected by manufacturers or may not be readily available.

Simulation and parameterization require in-depth expertise

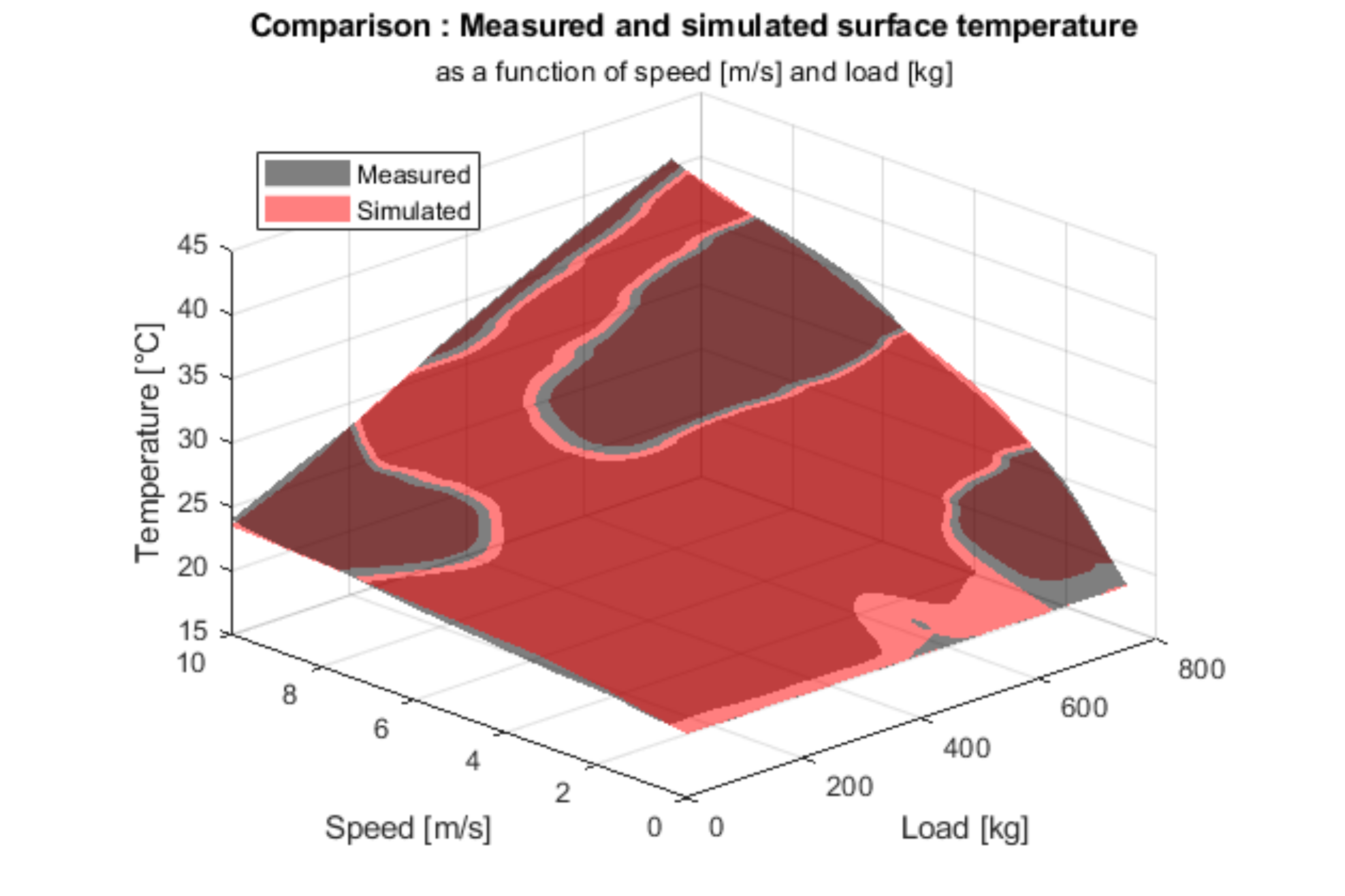

To create an accurate simulation model, unknown parameters are initially estimated. The simulation uses a speed profile as a reference to predict the thermal behavior under various operating conditions. The model is validated by measuring the thermal behavior of the tires under different speeds and loads and then comparing these measurements with the simulation results.

Experimental validation confirms the reliability of the thermal model

During the measurement campaign, the tires are tested with loads of up to 800 kilograms and speeds ranging from 5 to 40 kilometers per hour. The simulation reliably predicts the resulting surface temperature, demonstrating the model's reliability. This validation process is crucial to ensure the model's applicability in real-world scenarios.

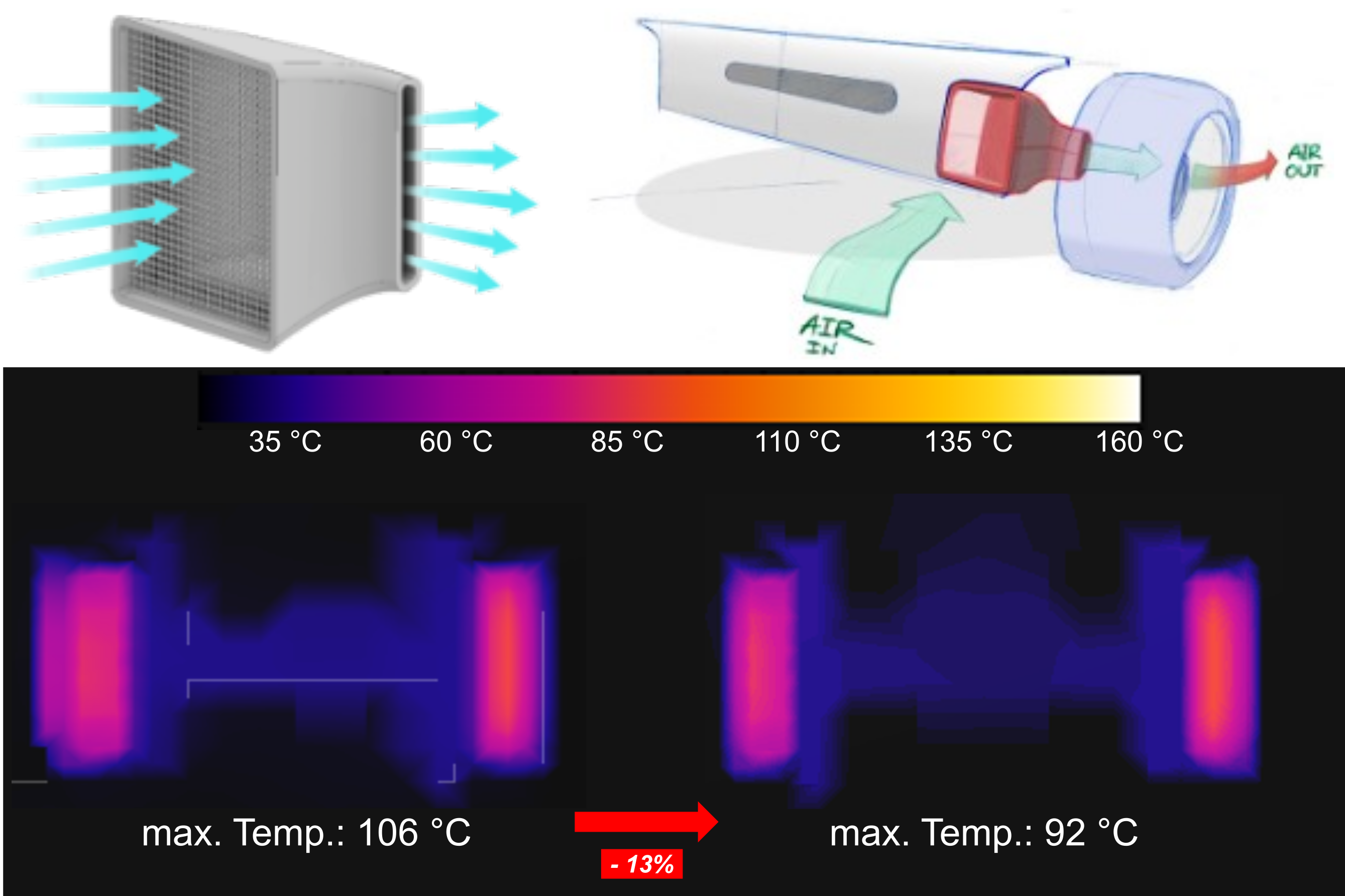

Passive cooling concepts have excellent efficiency

At higher speeds and loads, temperatures can exceed one hundred degrees Celsius over extended periods, requiring effective cooling to ensure tire safety and longevity. Passive cooling solutions have proven to be the most efficient in this context. These solutions utilize the airflow generated by vehicle movement, as shown in Figure 6. Spatial fluid and conjugate heat simulations demonstrate the benefits of passive air cooling. They also provide guidelines for design optimizations to maximize cooling efficiency.

Alternative approaches, such as water or active air cooling, offer higher cooling performance, especially when stationary or at lower speeds. However, they are technically more complex and less energy efficient.

Summary: Predictive simulation models optimize cooling solutions for solid rubber tires

Solid tires offer significant advantages for autonomous transport vehicles due to their durability and low maintenance requirements. However, controlling their thermal behavior is crucial for safety and performance. Detailed simulation models demonstrate the importance of effective cooling systems for the use of solid tires and how these cooling systems must be designed to provide the necessary cooling performance at high speeds.

Helbling provides a robust tool for predicting tire behavior under various conditions through the development and validation of thermal simulation models, supported by extensive technical data and experimental validation. Based on this, effective solutions, such as passive cooling systems, can be identified to ensure optimal tire performance and longevity.

Authors: Simon Müller, Martin Thibault

Main Image: Helbling