reference project

Optimization of the Power Converter Cooling System within the Scope of the BLS RABe 525 (NINA) Retrofit

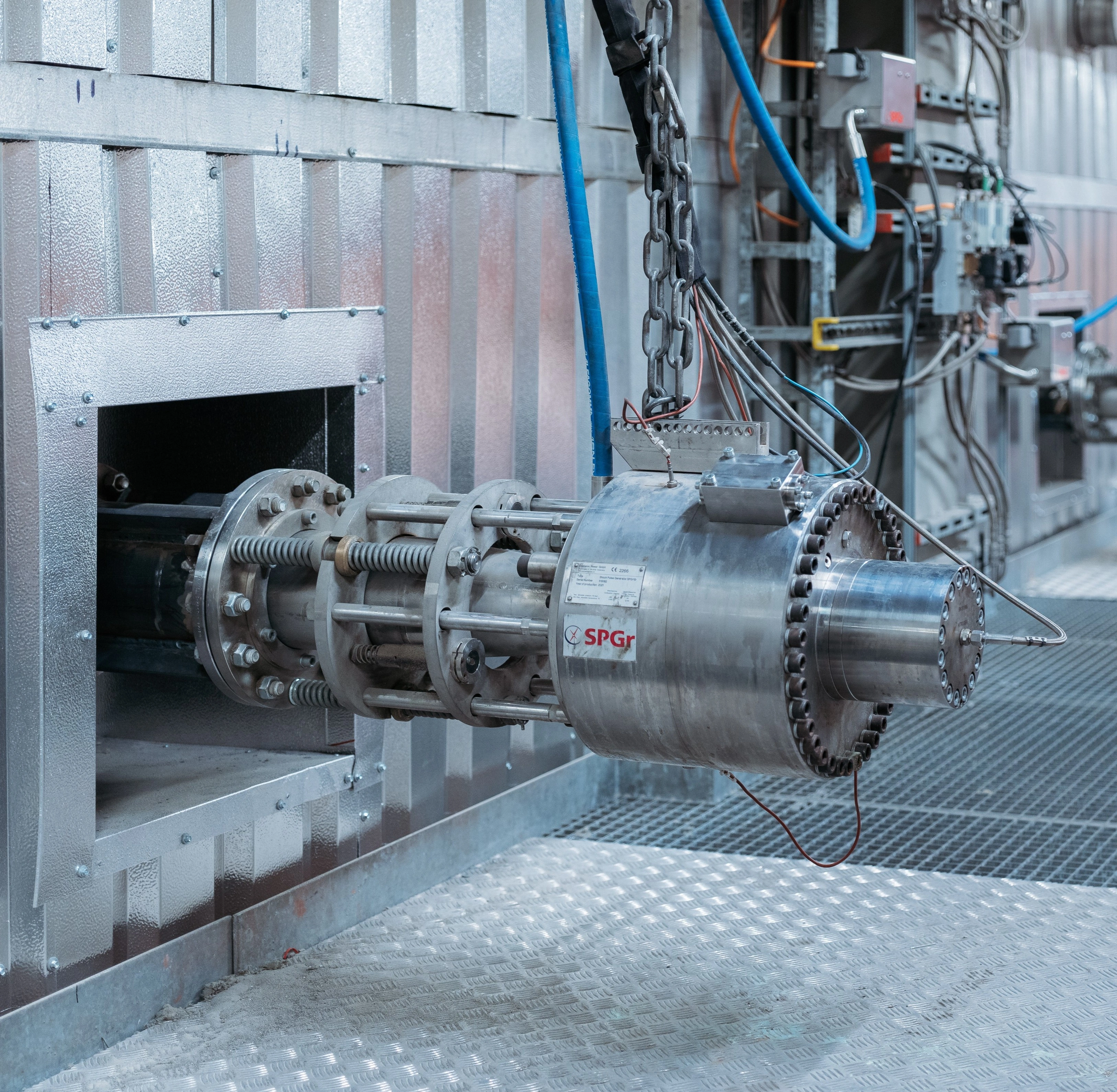

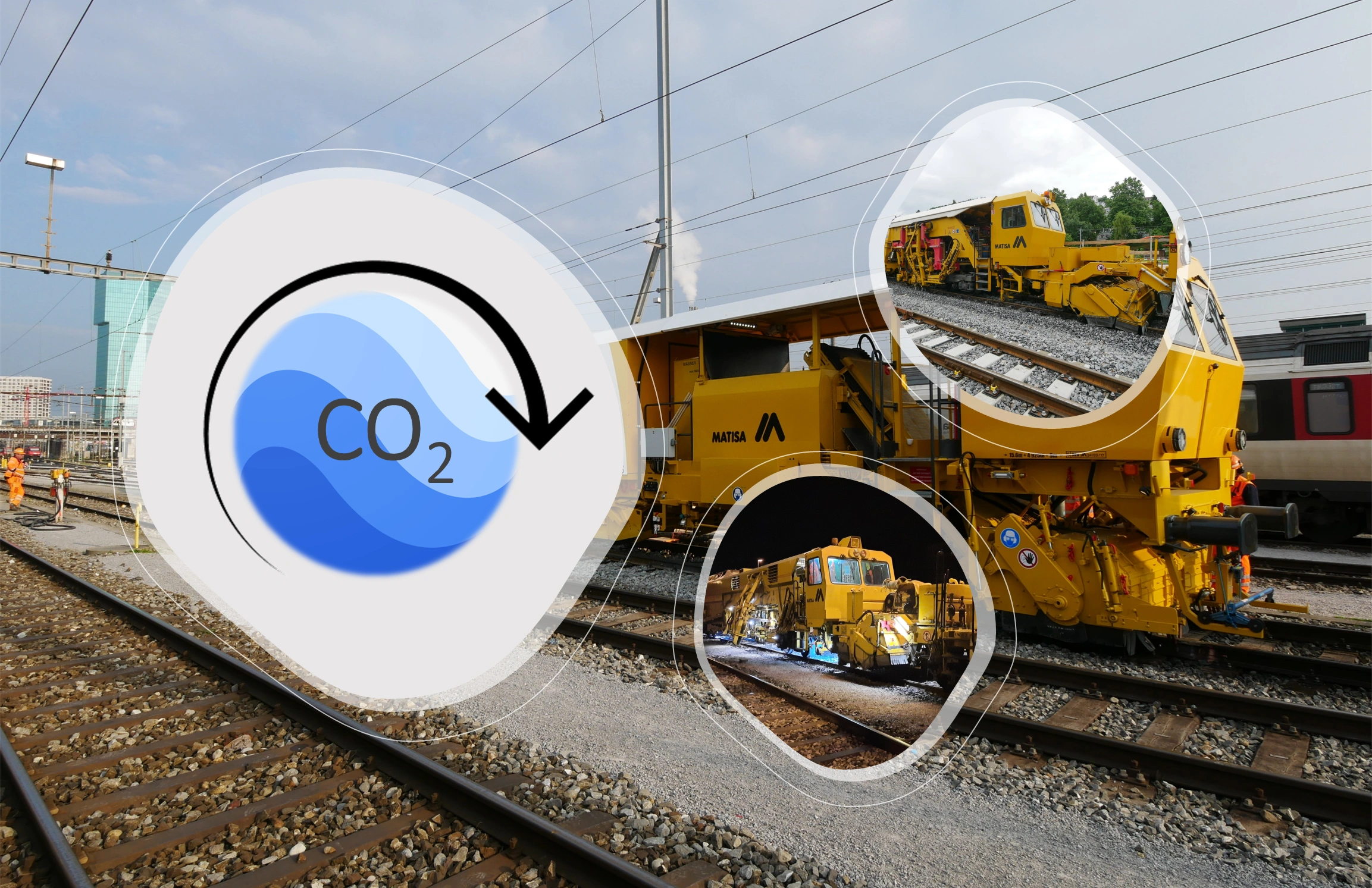

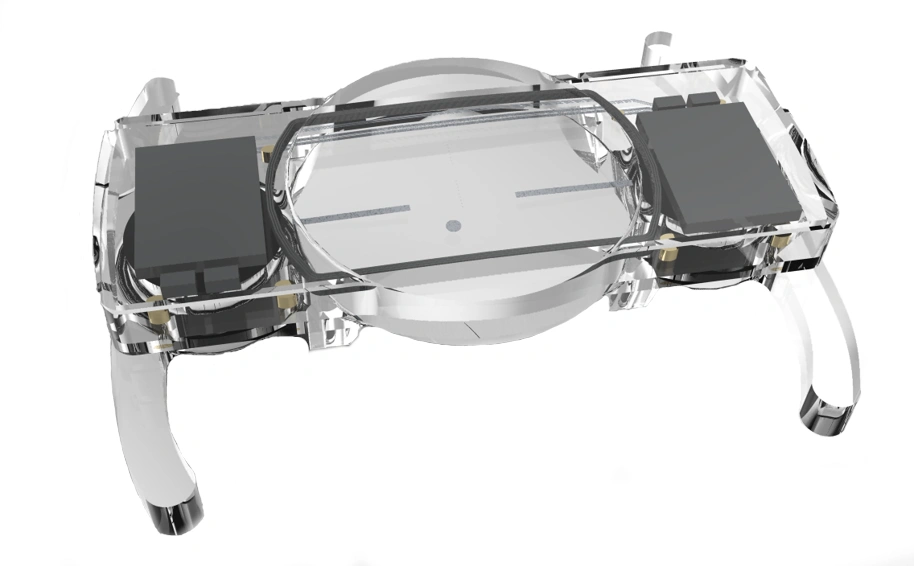

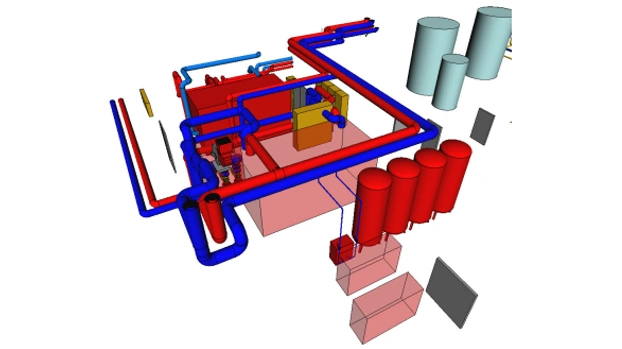

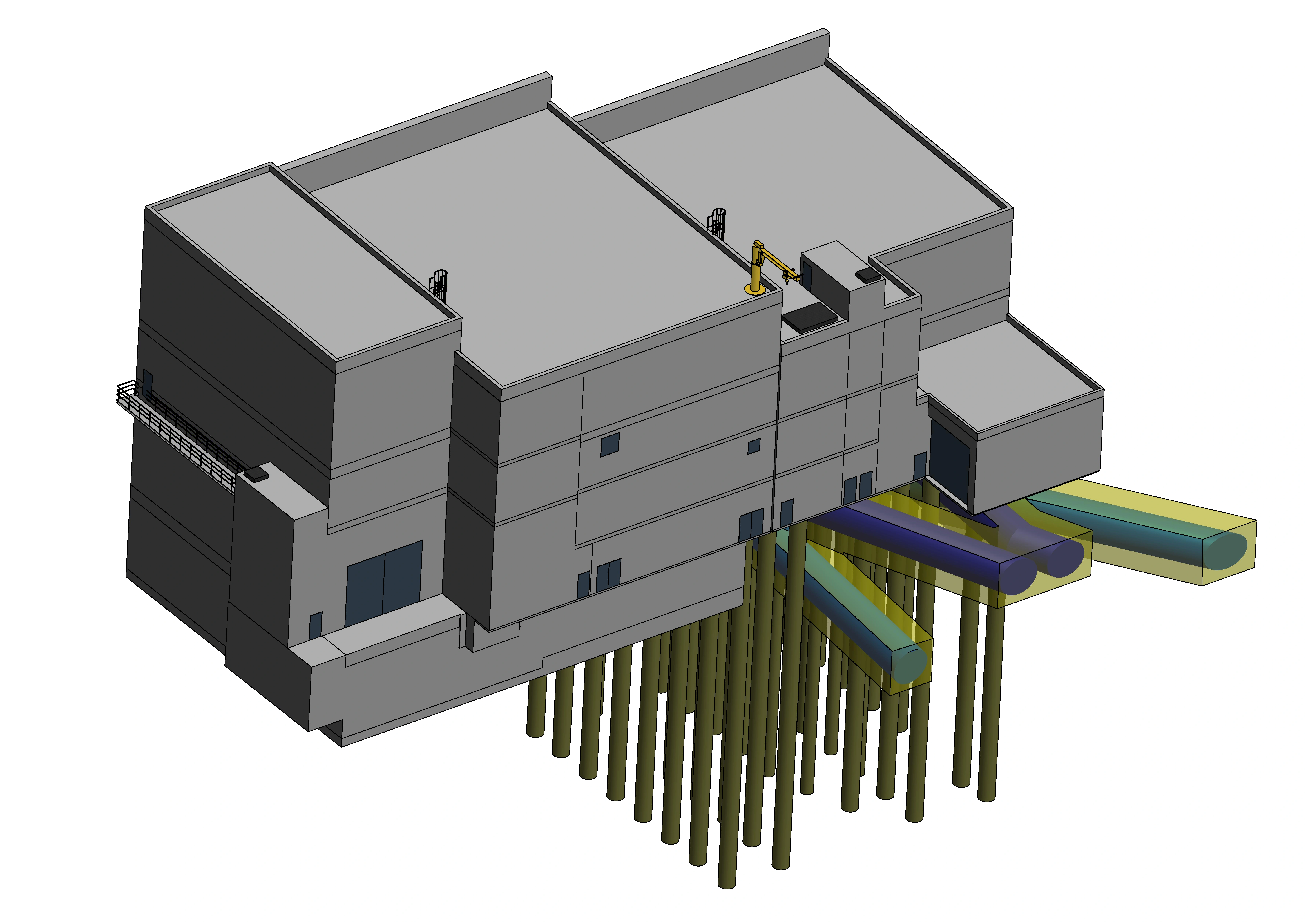

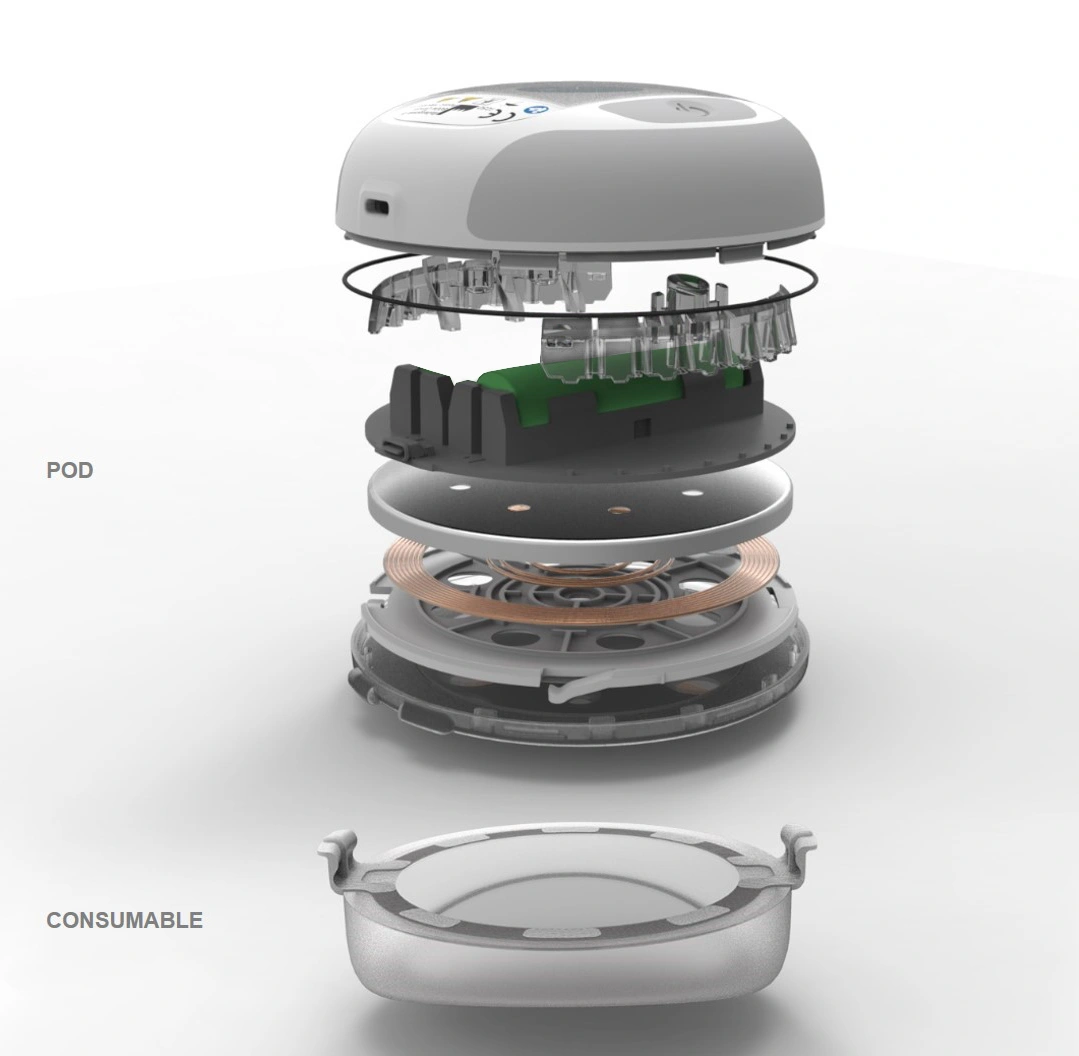

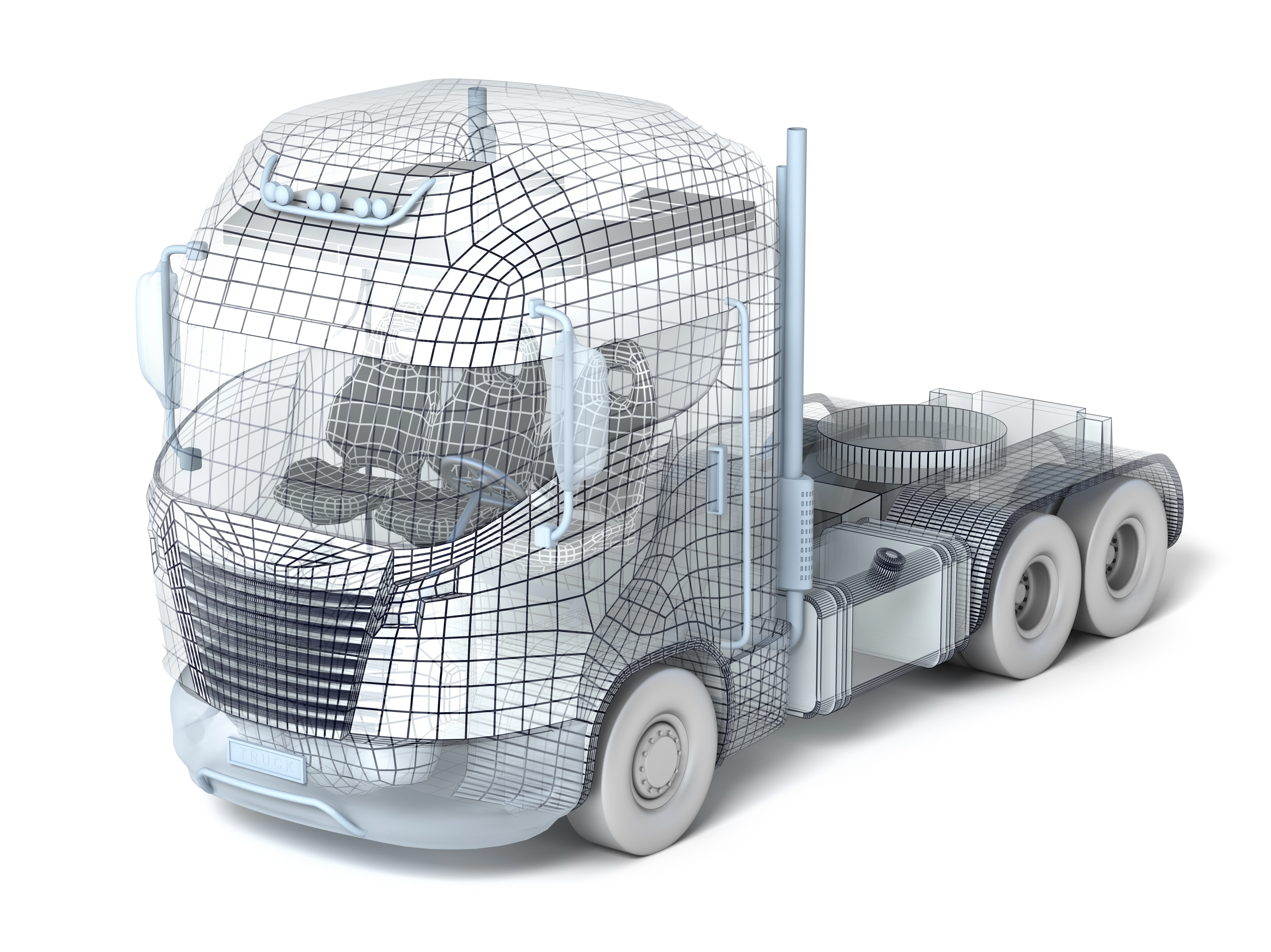

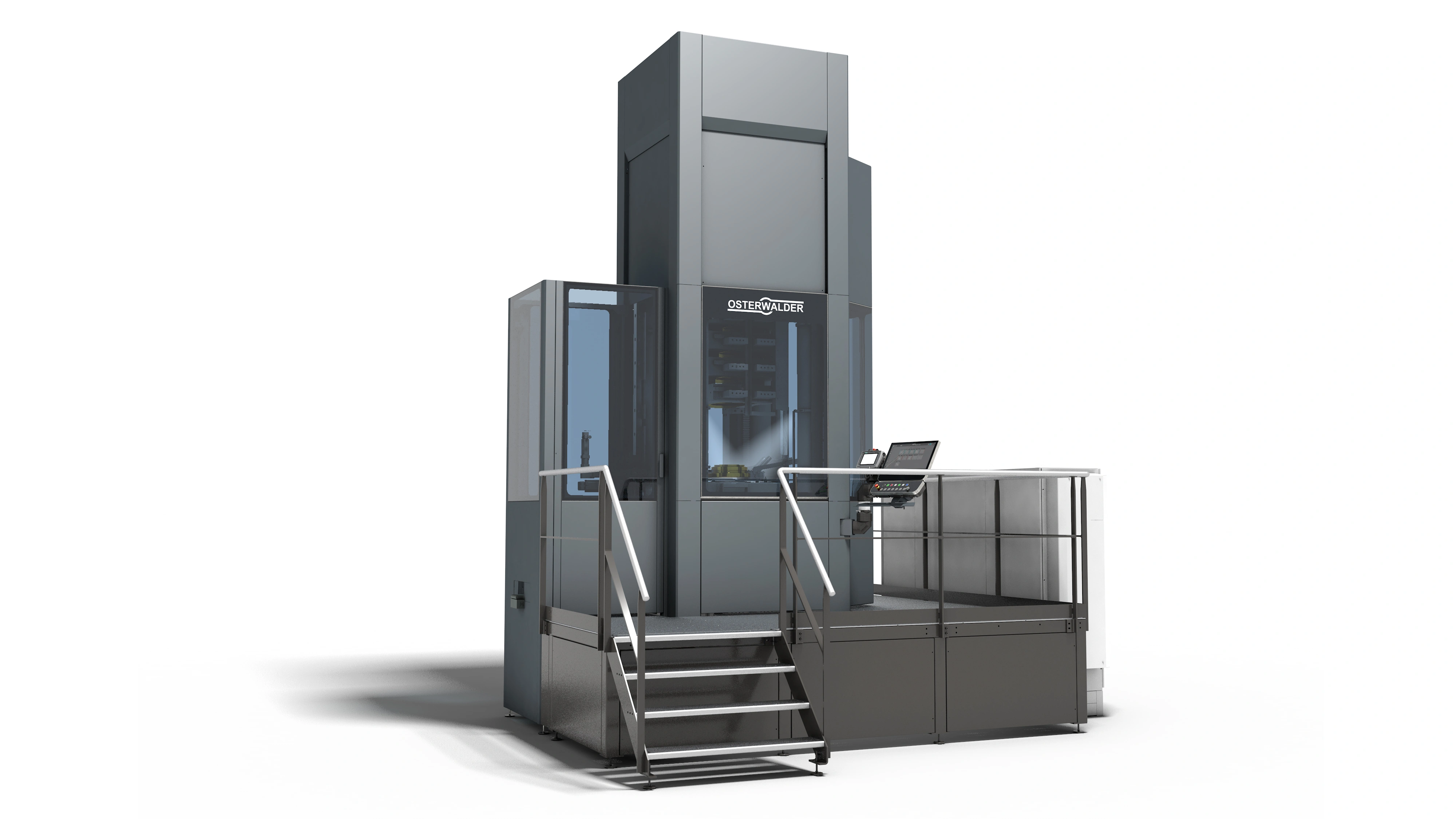

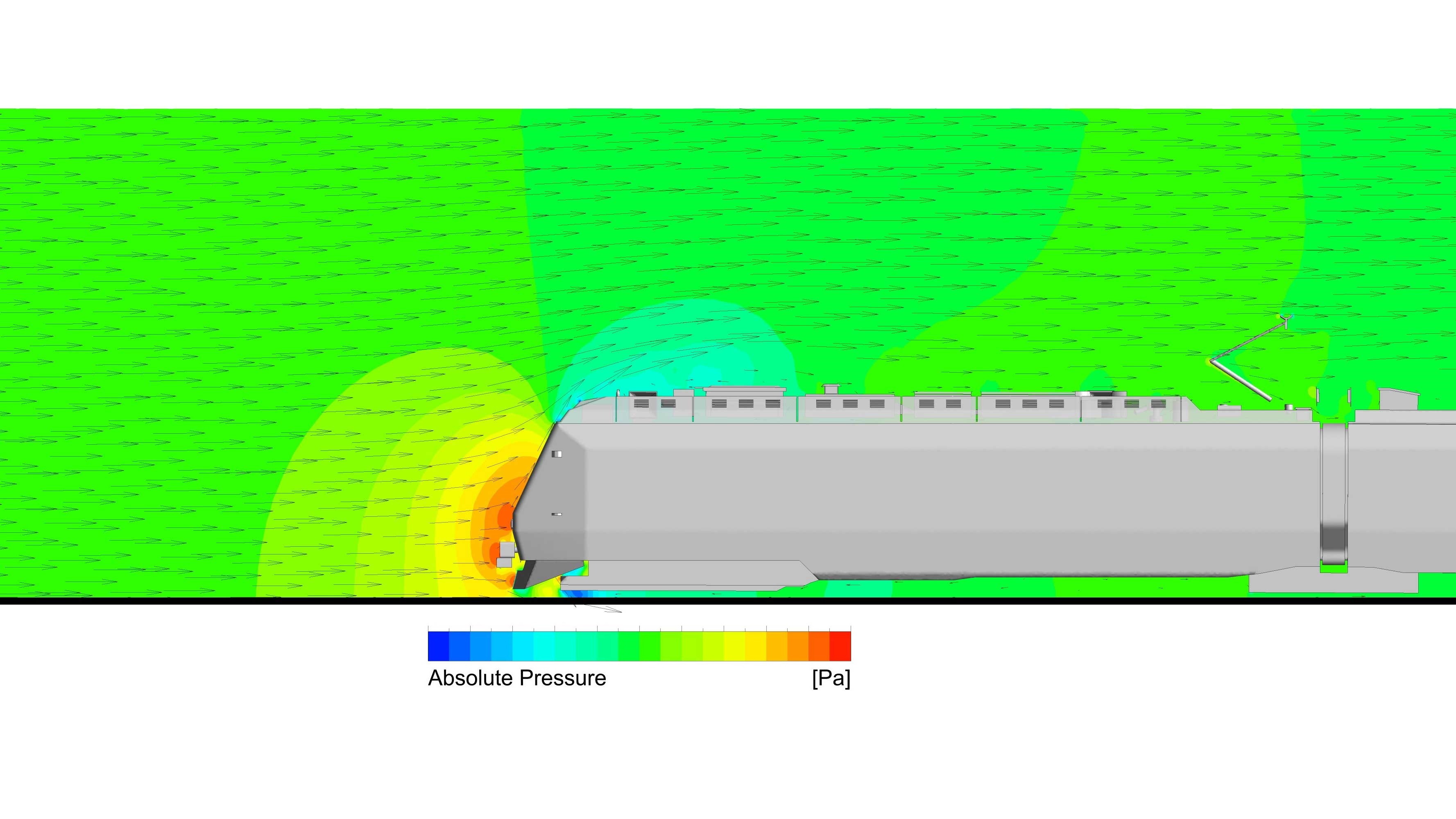

In 2015, BLS AG launched a three-year retrofit project for its 36 NINA multiple units (low-floor commuter trains). These include the optimization of the cooling system for the rooftop power converters in compliance with new requirements. Helbling analyzed the factors that had previously limited cooling capacity and used these insights to devise improvements.

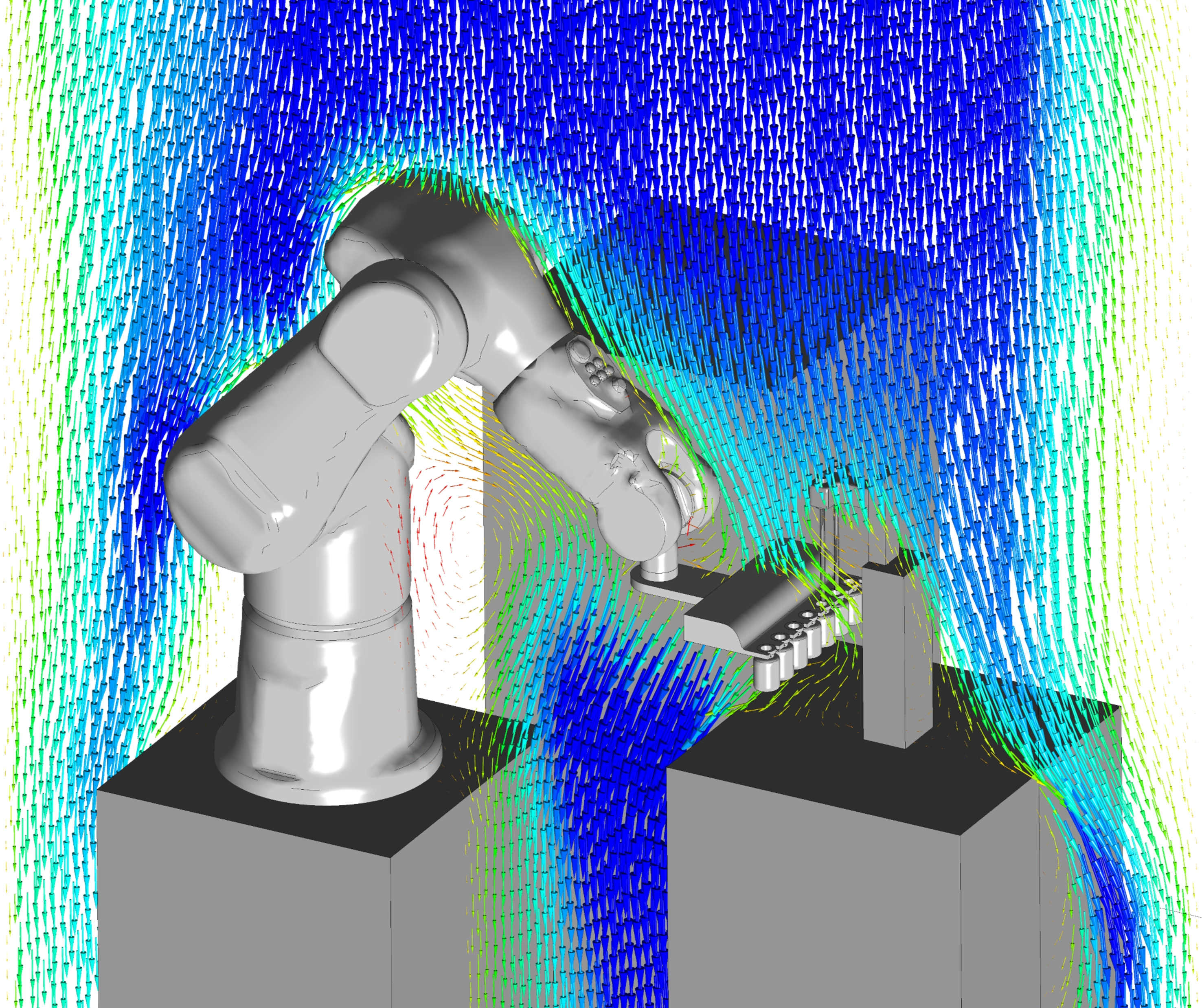

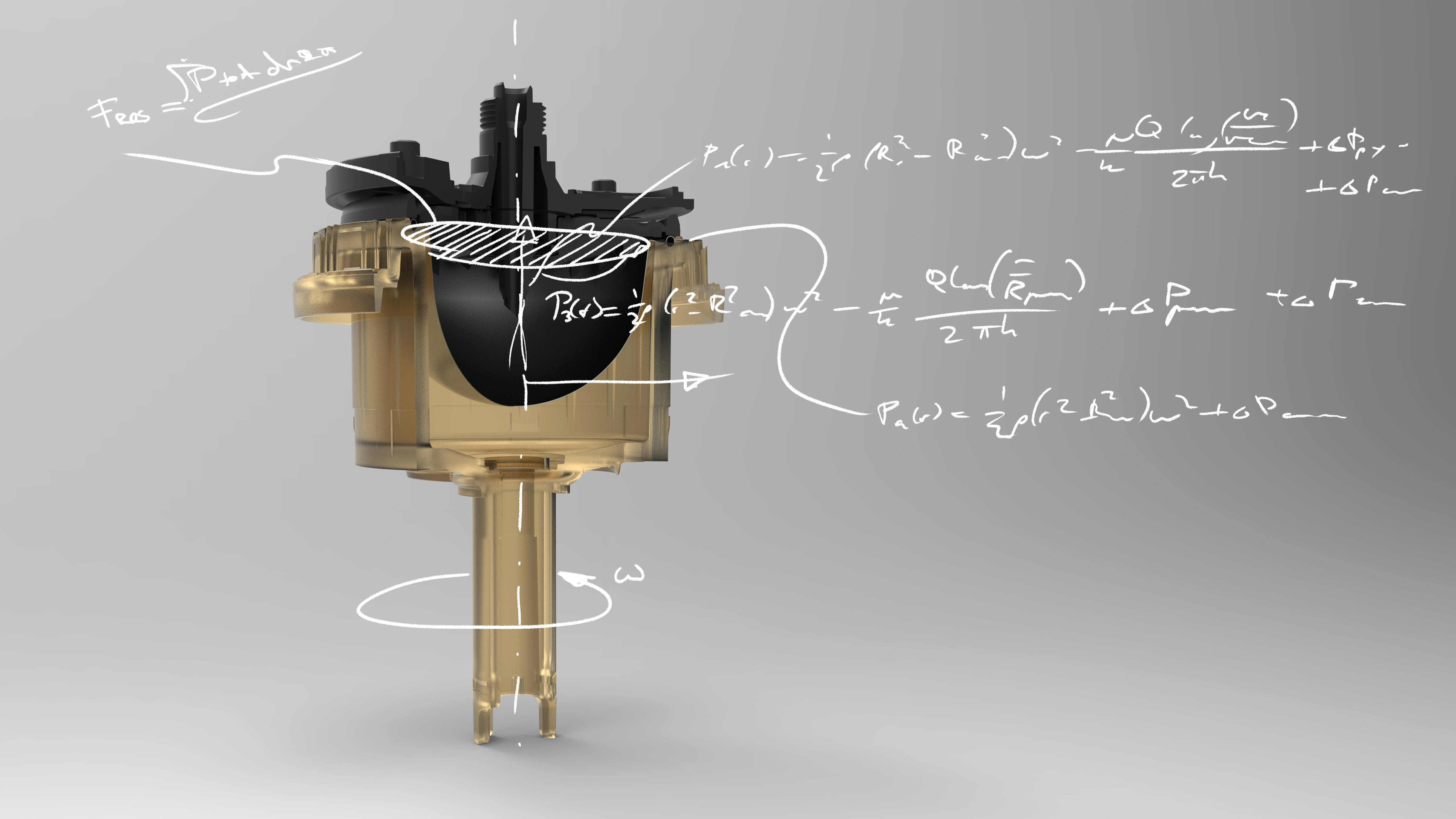

The power converter cooling system on the roof of the NINA multiple units had reached its limit. The limiting factor, however, was unknown. Helbling's task was therefore to find a way to efficiently analyze and optimize the cooling system. In its capacity as a center of excellence for rail vehicles, Helbling was able to draw on many years of experience, particularly in the area of modernization and retrofit projects.

Key Figures

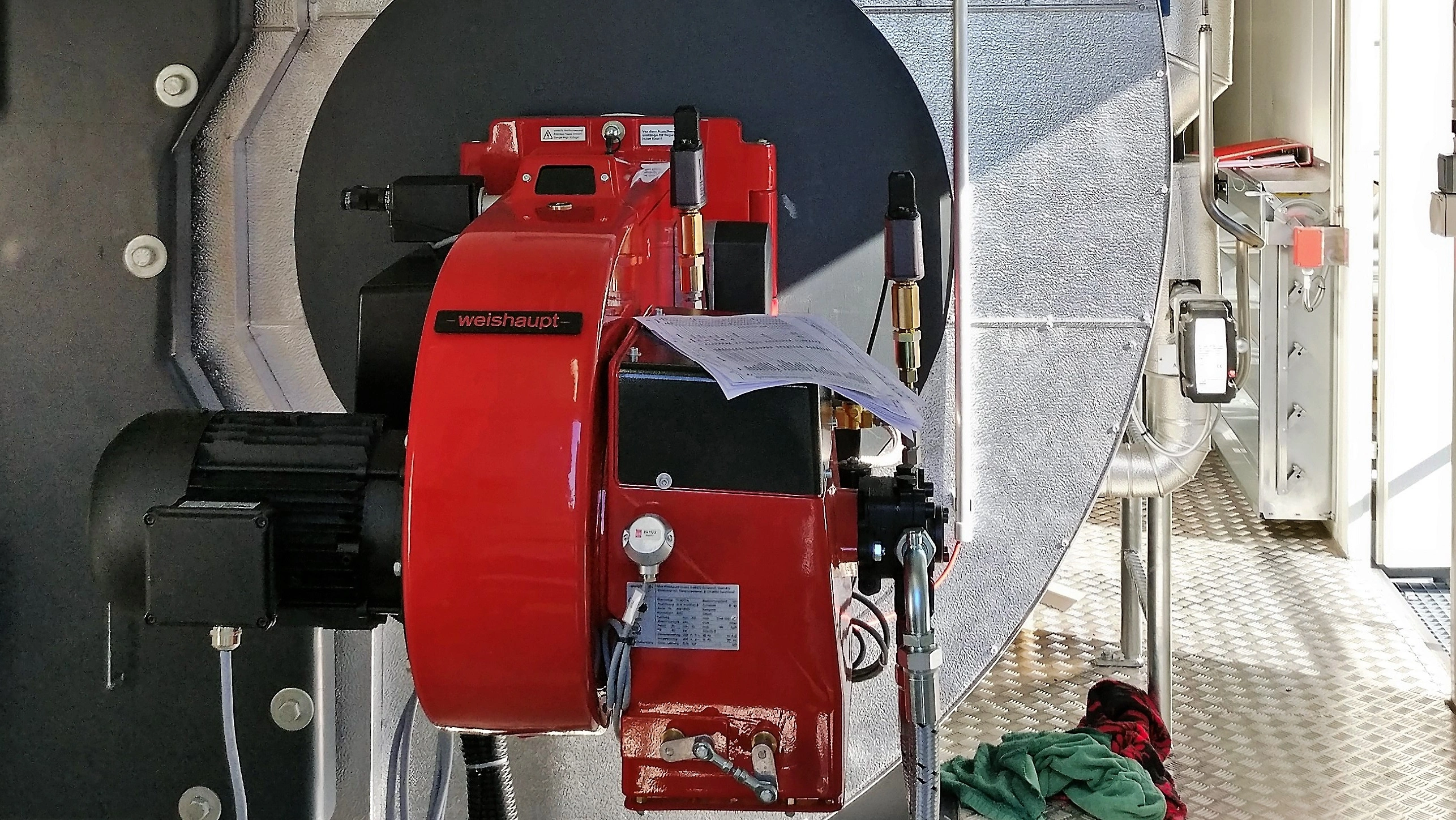

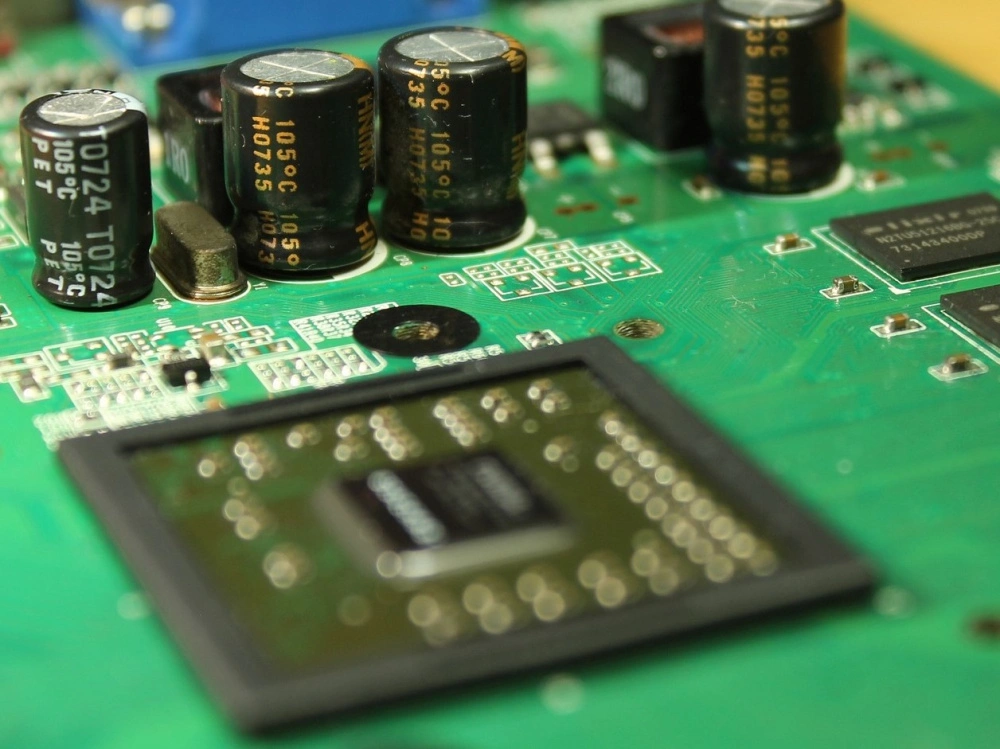

- Power converters convert the 15 kV 16 2/3 Hz overhead line voltage into a variable three-phase alternating current for the traction motors

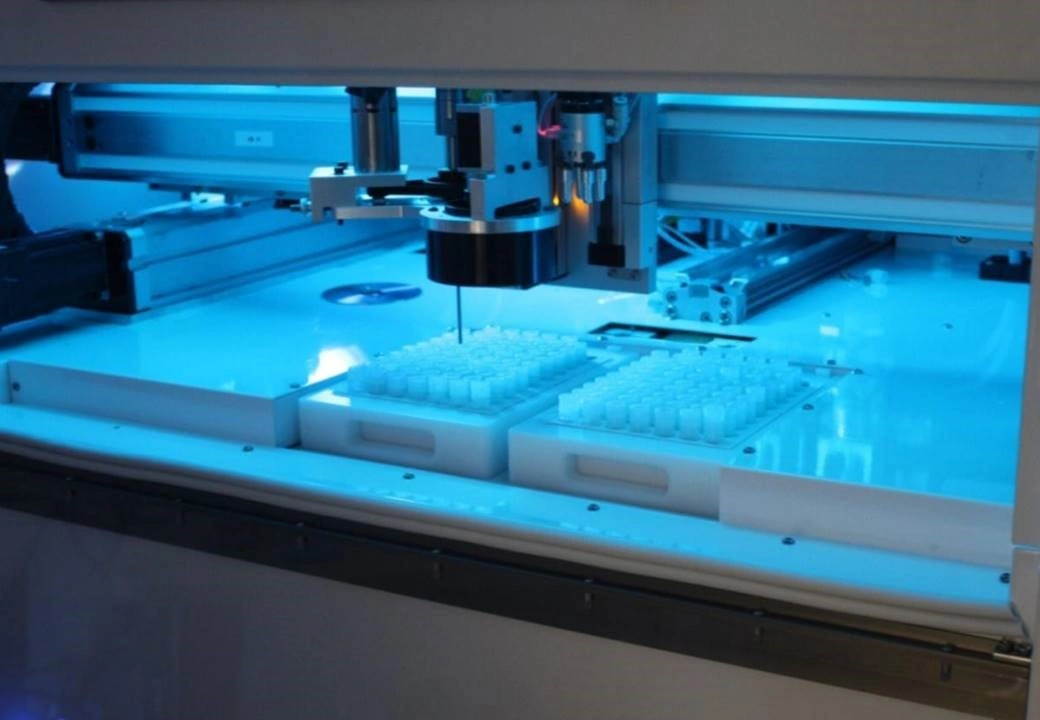

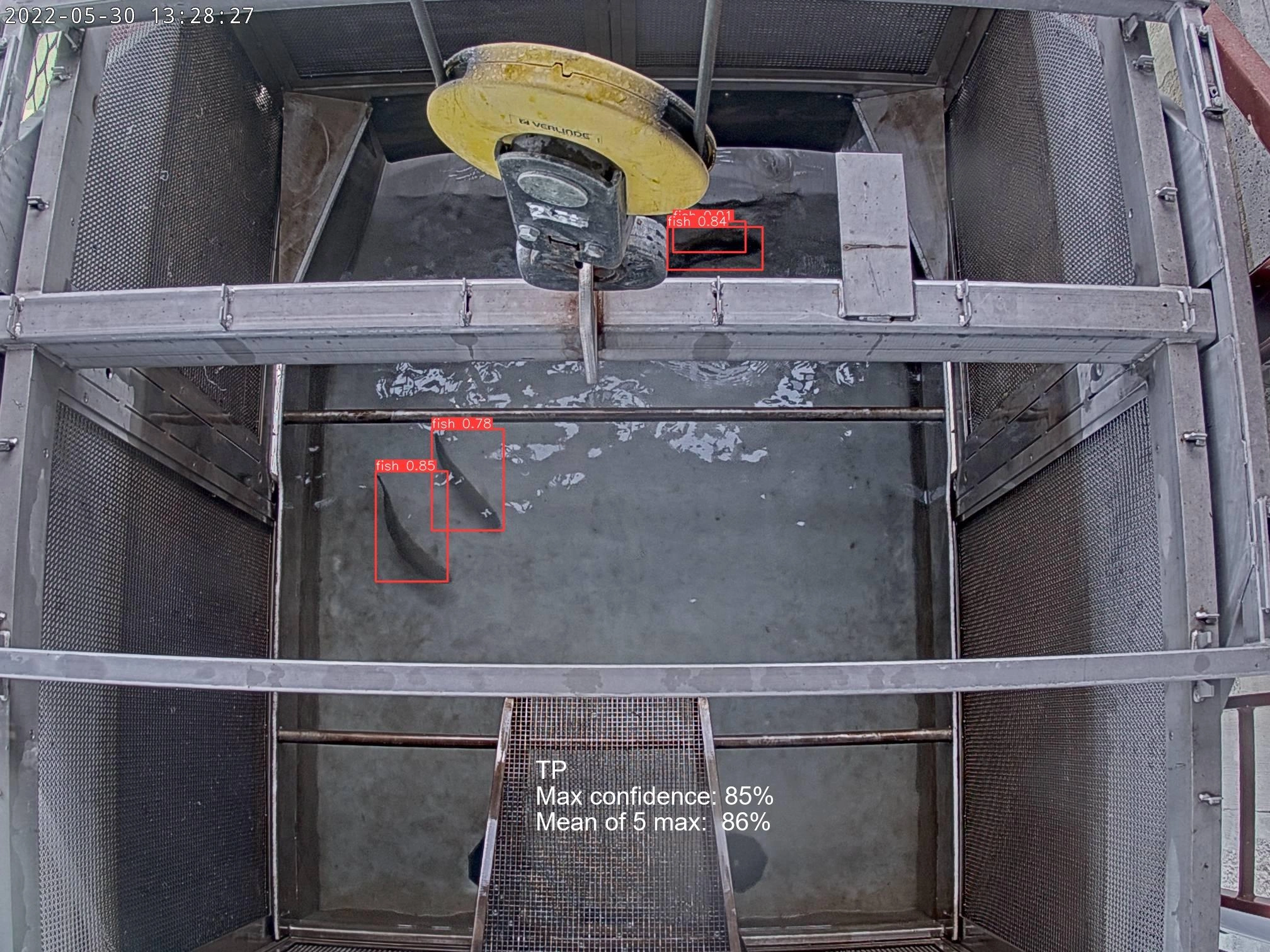

- The power converters are air-cooled. Cooling air is drawn in by a radial fan near the roof and blown through the power converters at the ambient temperature

- The cooling system for the power converters must not limit the power supplied to the traction motors

Our Contribution

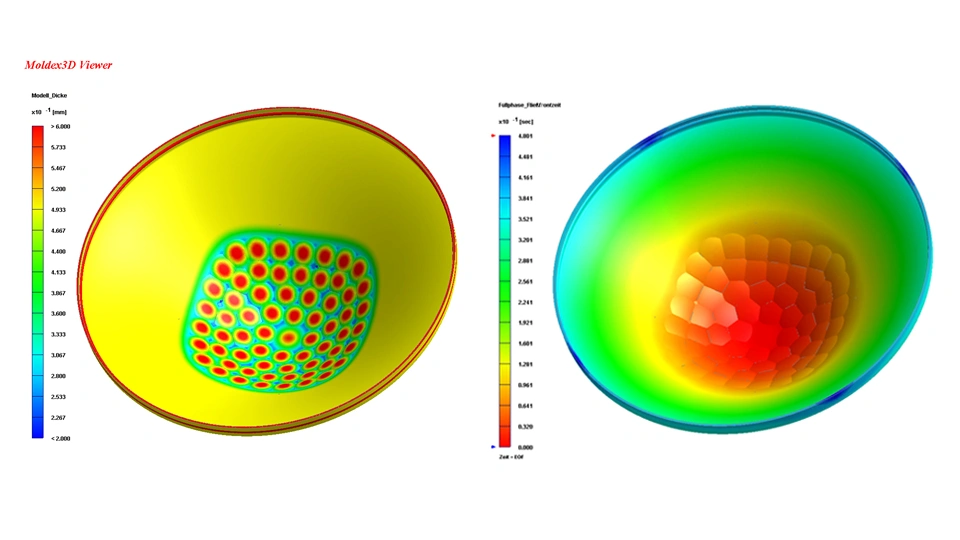

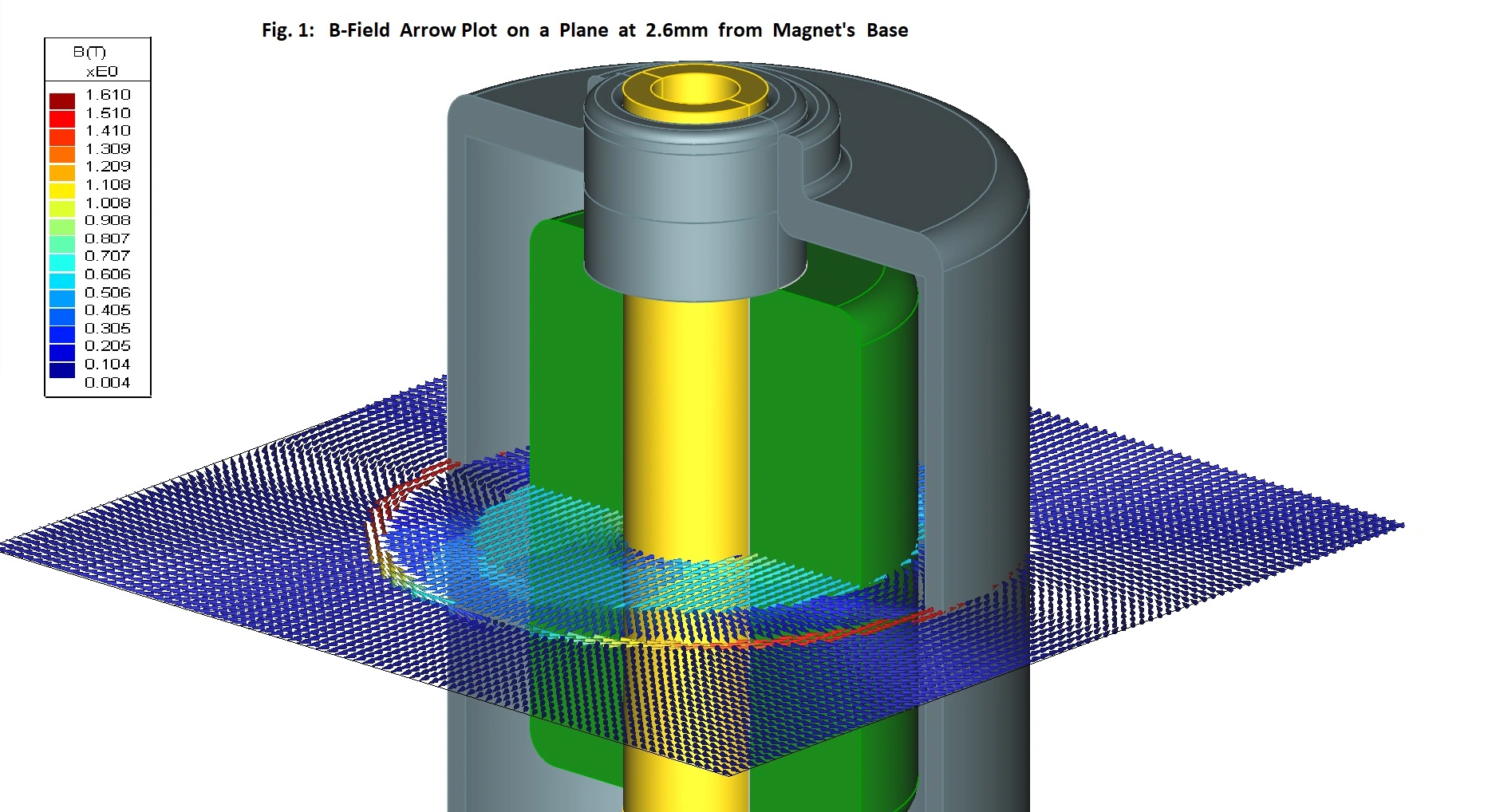

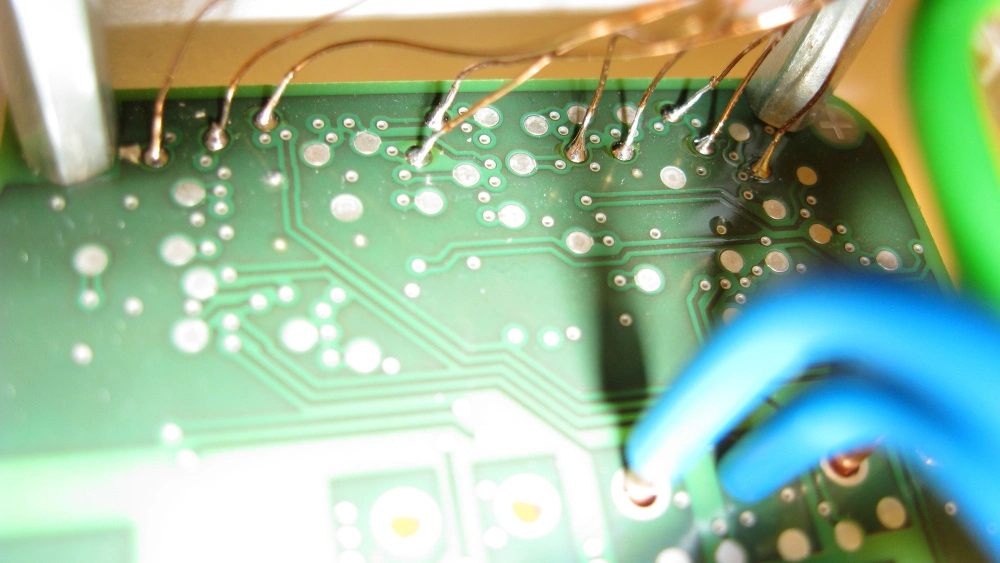

- Initial estimate and diagnosis by Helbling

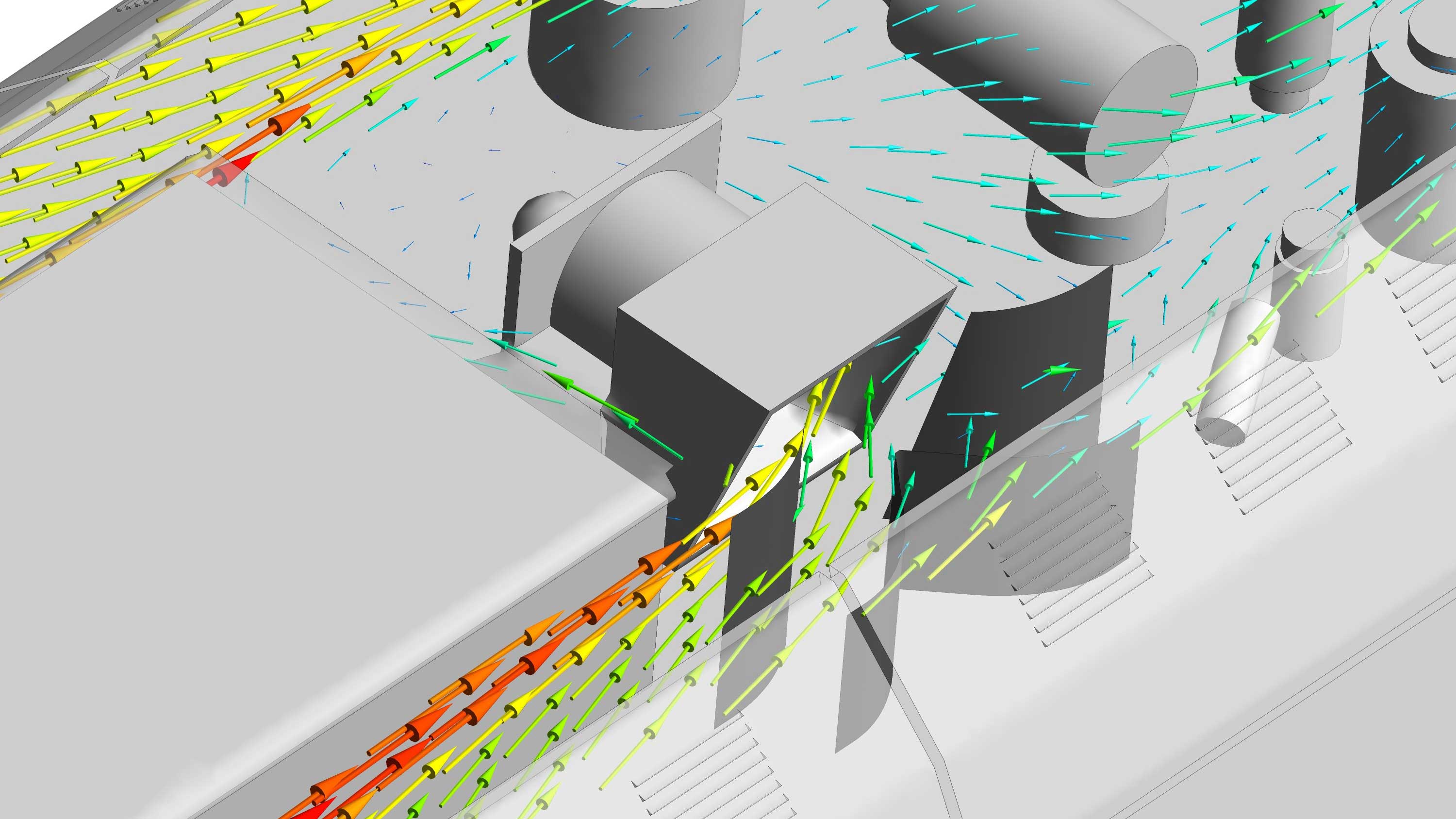

- Restriction to two possible causes for cooling limitations

- Systematic IST analysis for both possibilities with clear results

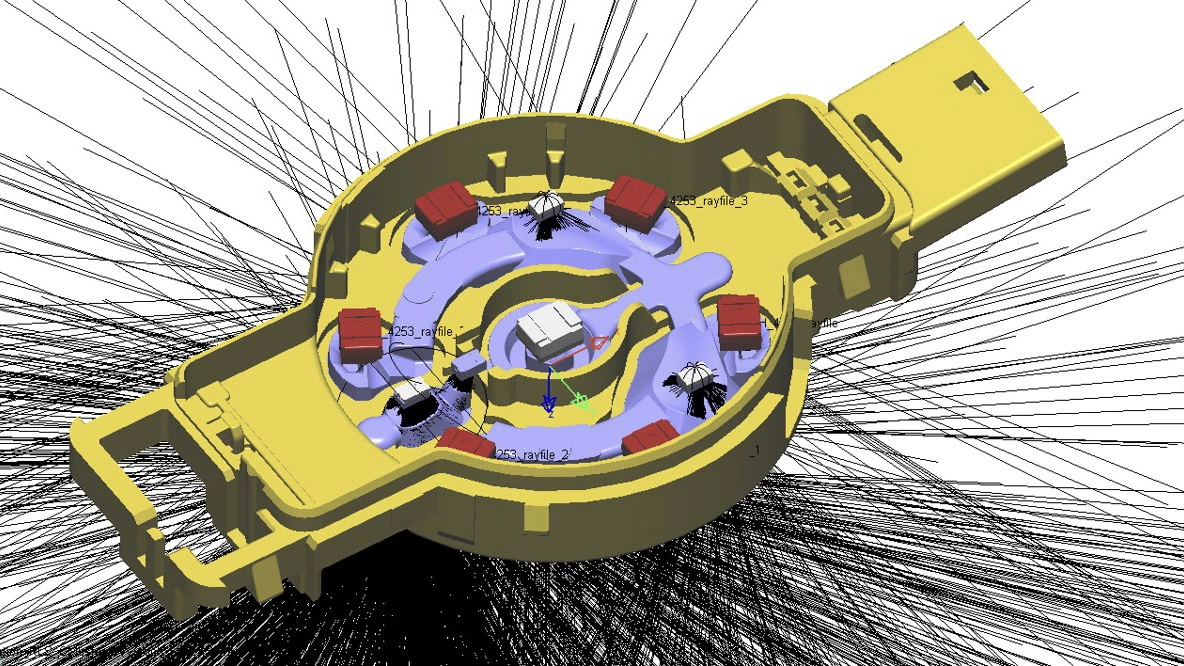

- Development of concept for optimizing inflow to power converter fan using baffles

- Iterative process for optimal design of baffles

- First retrofit as prototype

Outcome

The results of the air flow analyses tallied extremely well with BLS's experience and measurements and could be used to explain previously unexplainable phenomena.

The proposed solution allowed the continued use of power converters, fans and other peripherals without any changes required.

By optimizing the power converter cooling system, the company has helped ensure that the vehicles can continue to be used cost efficiently for another 15 to 20 years.

Contact

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

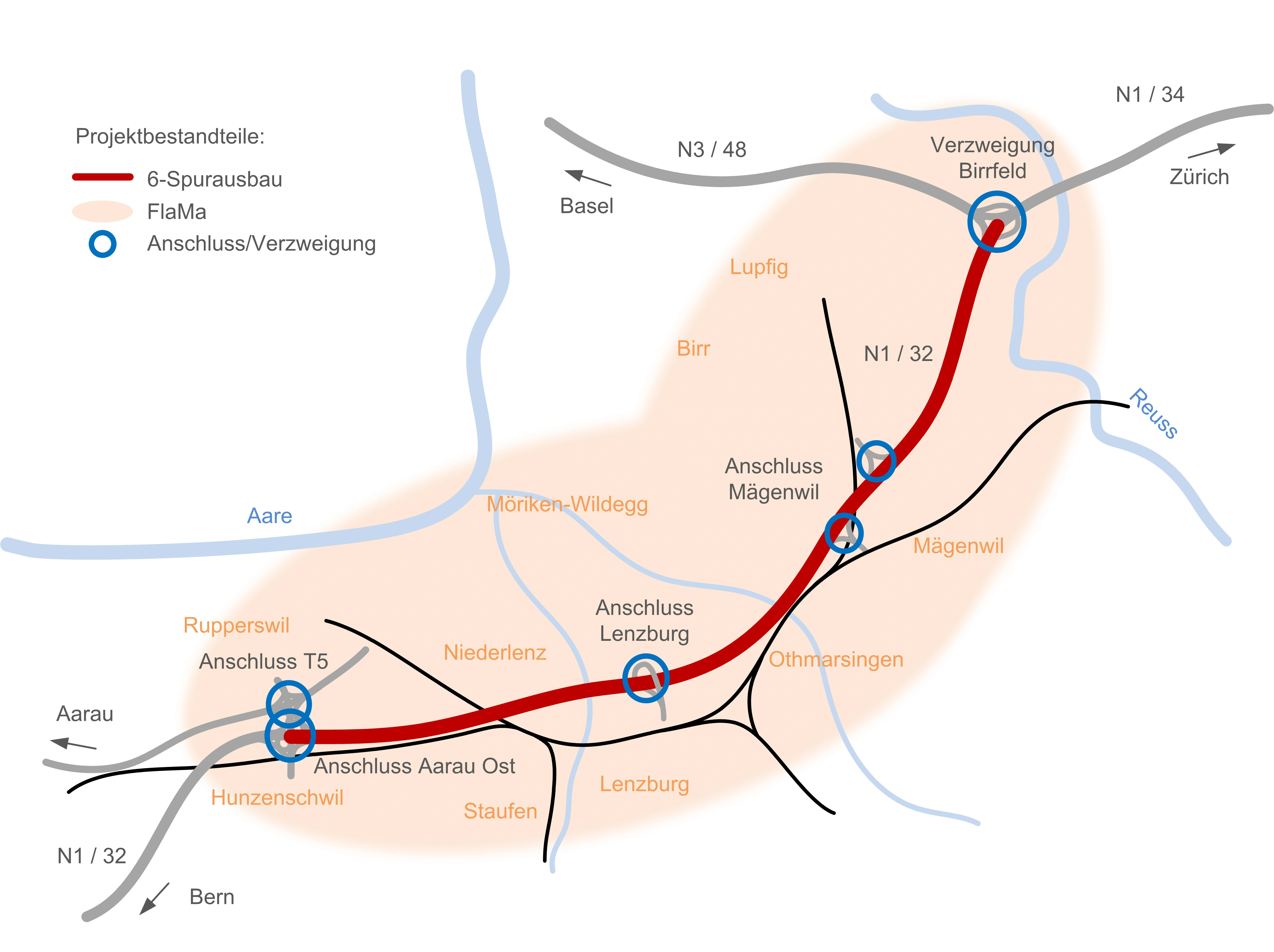

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: