Referenzprojekt

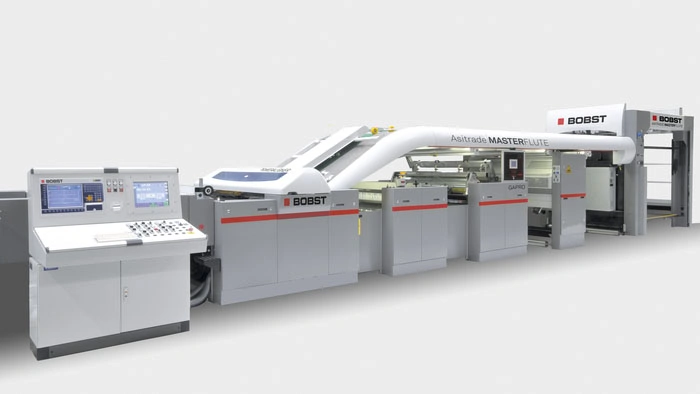

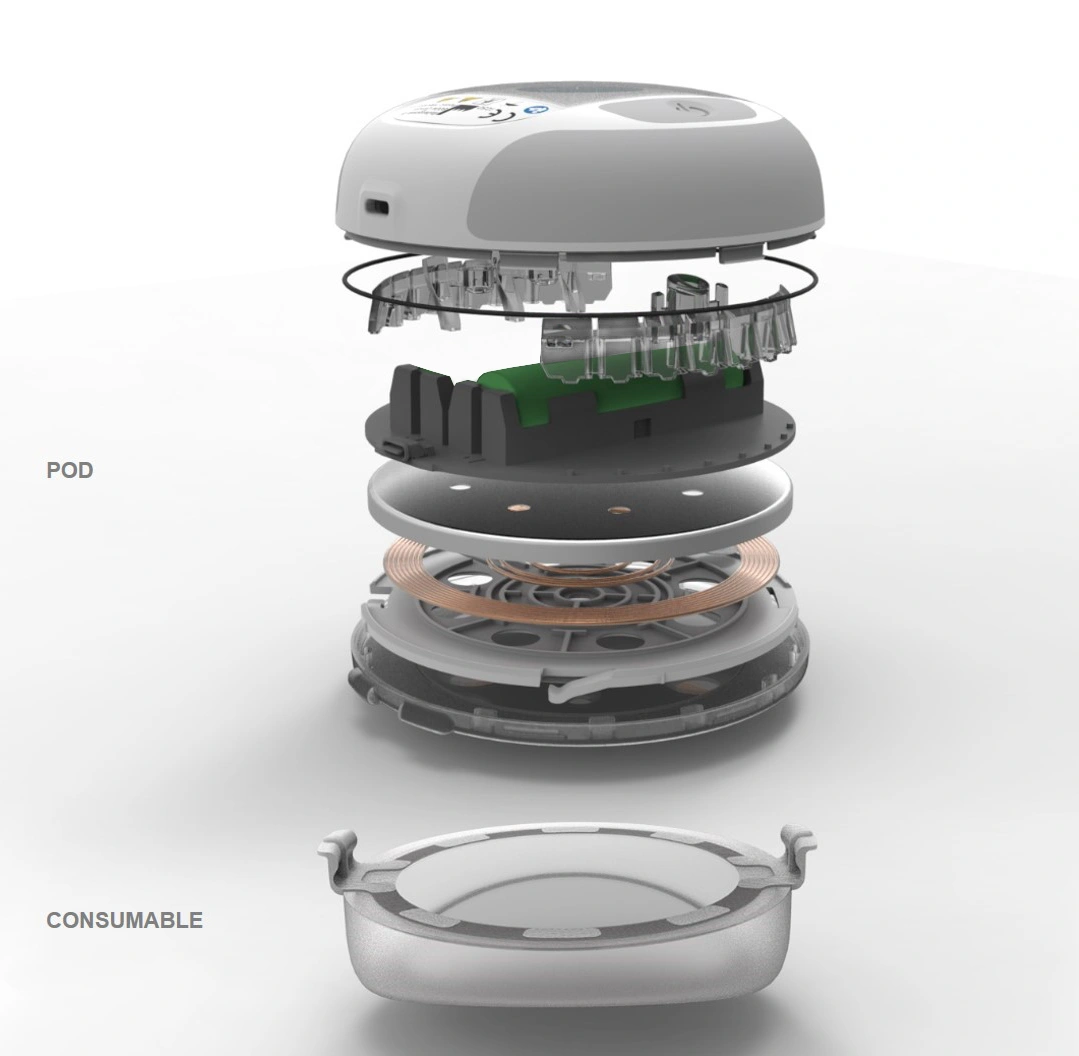

Shock Pulse

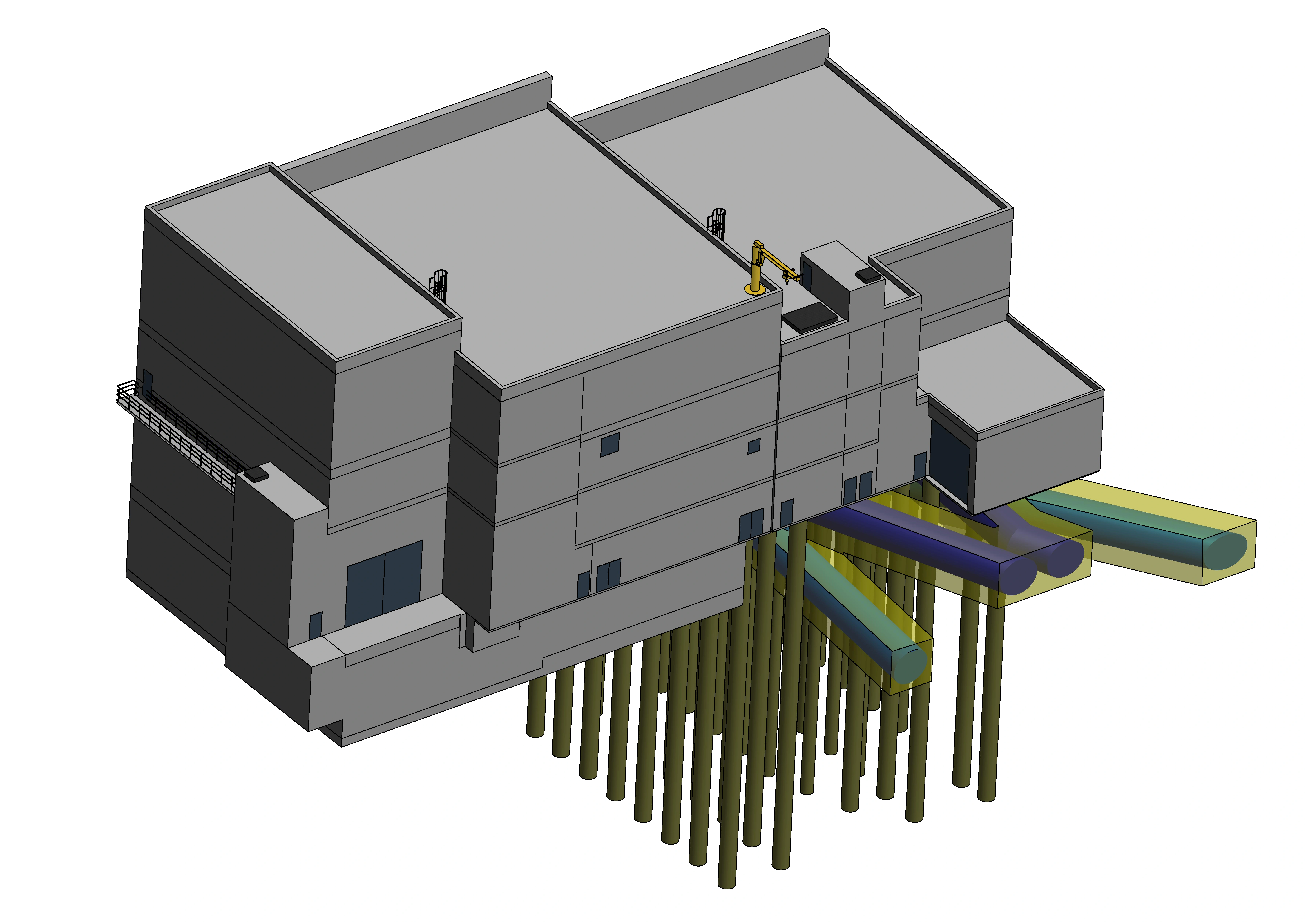

Generator: Redefining Efficient Boiler Cleaning

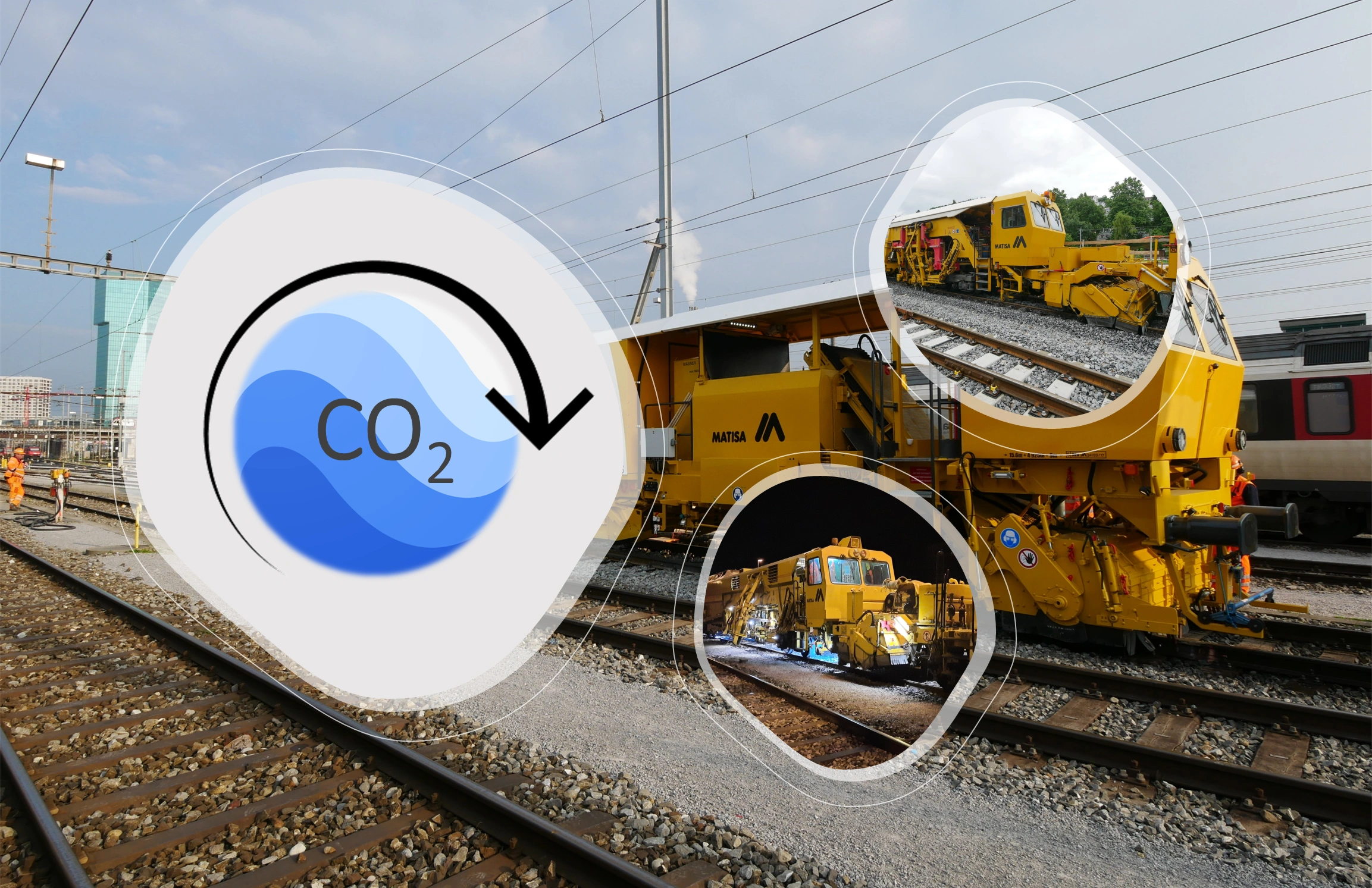

Explosion Power is a medium-sized Swiss company specialising in the development and production of innovative boiler cleaning systems. The solutions offered by Explosion Power combine years of experience, technological innovation, and Swiss quality standards – with the goal of continuously improving the operational reliability and performance of thermal power plants.

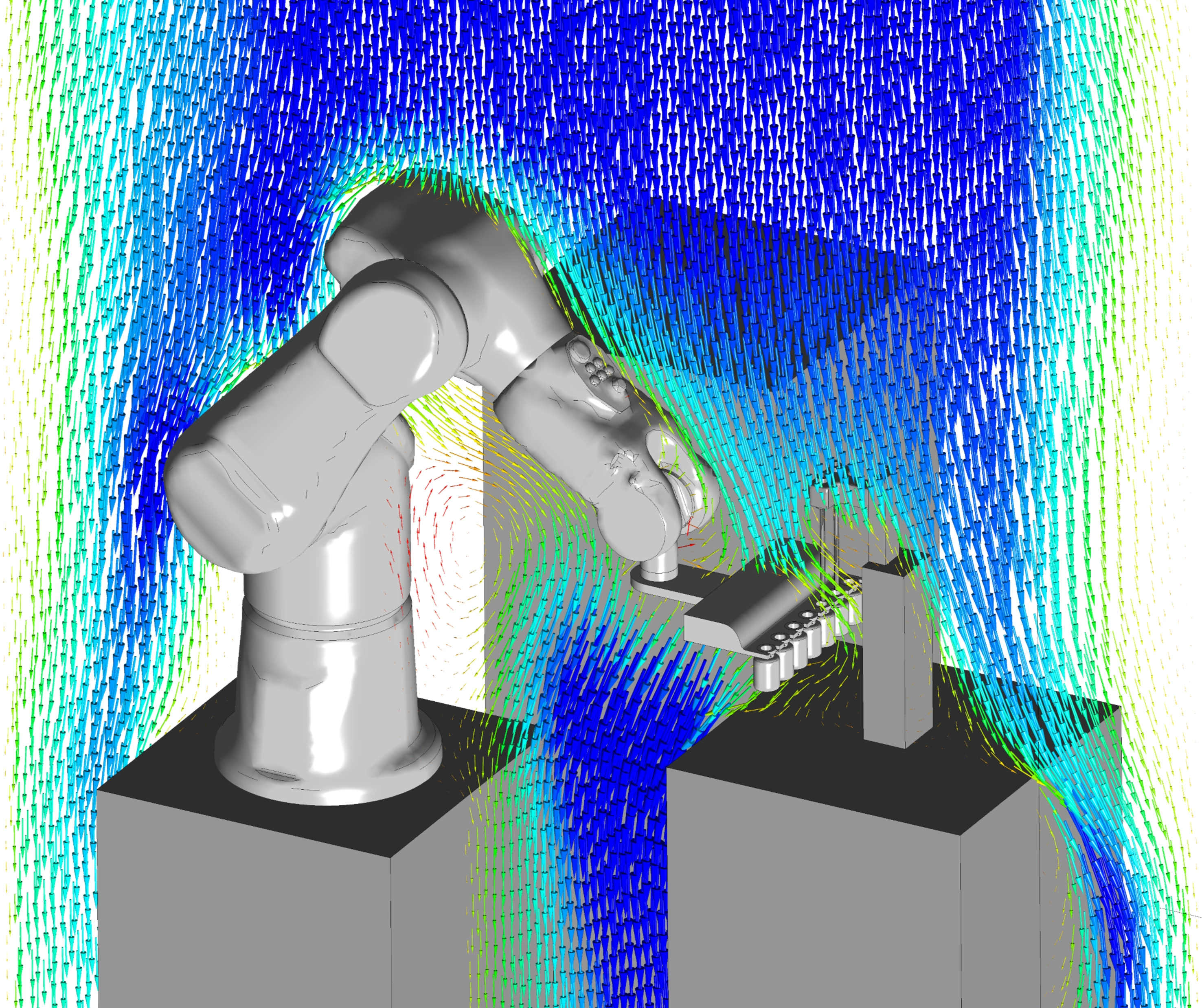

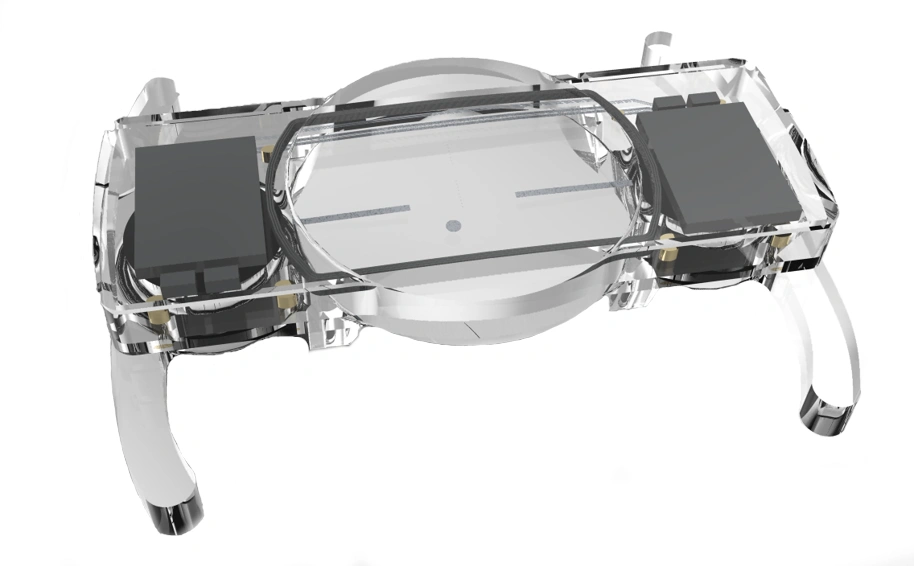

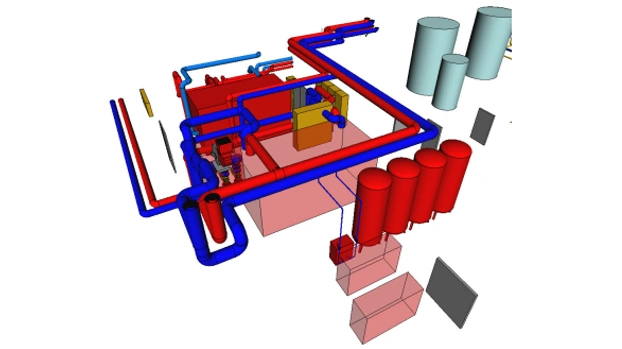

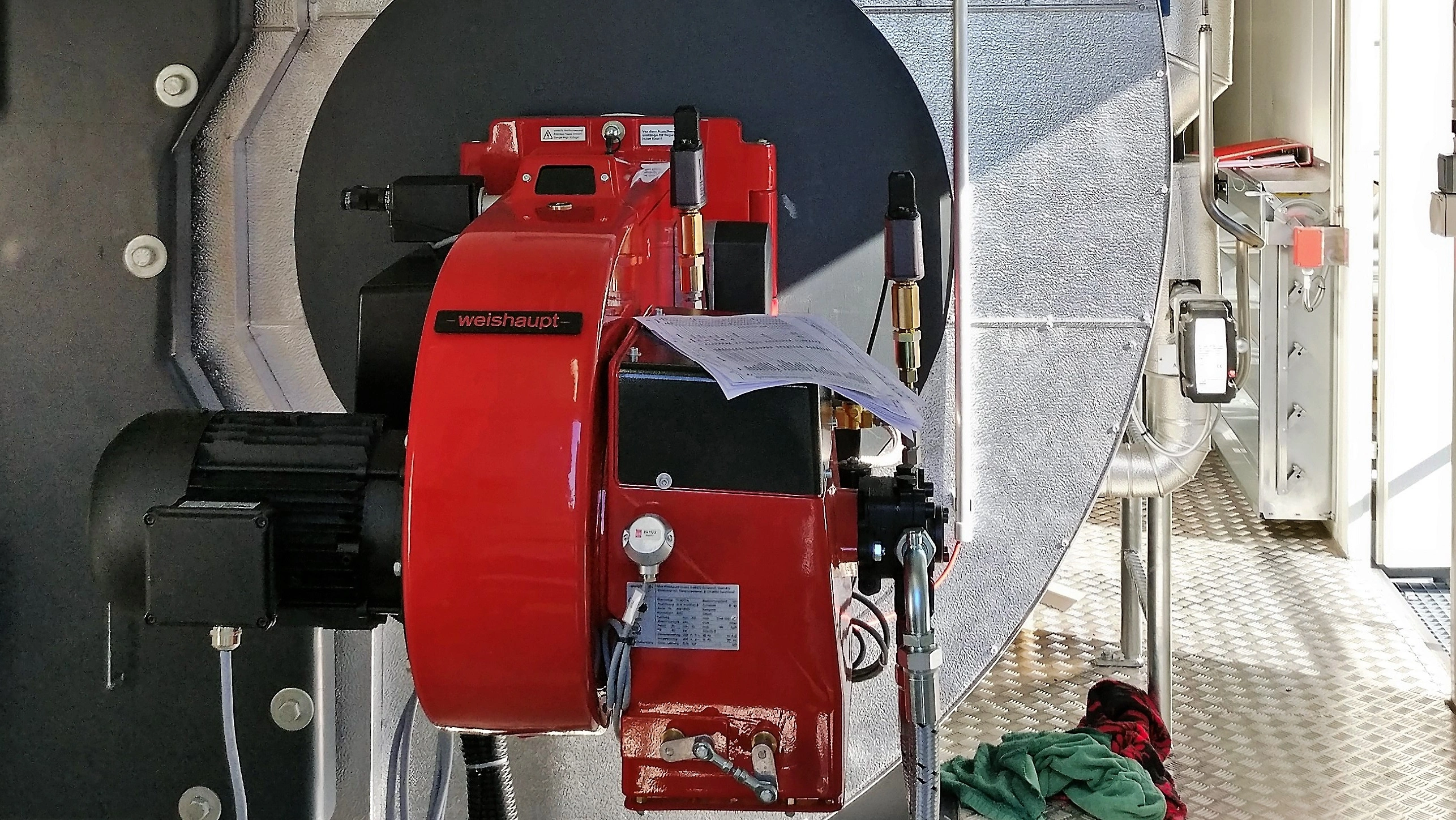

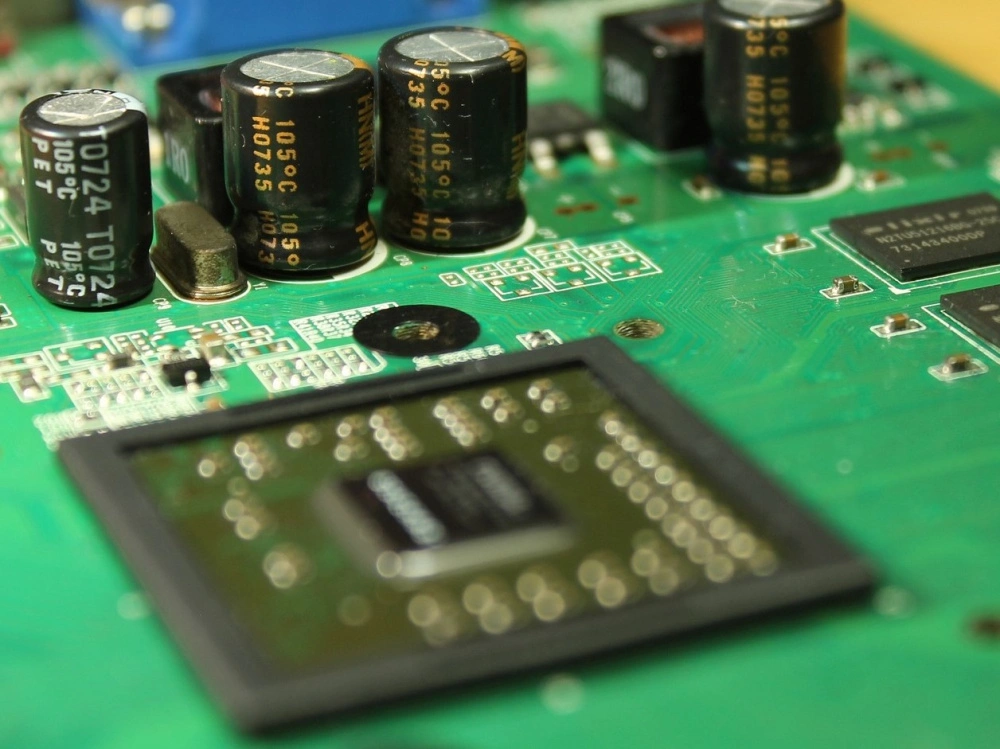

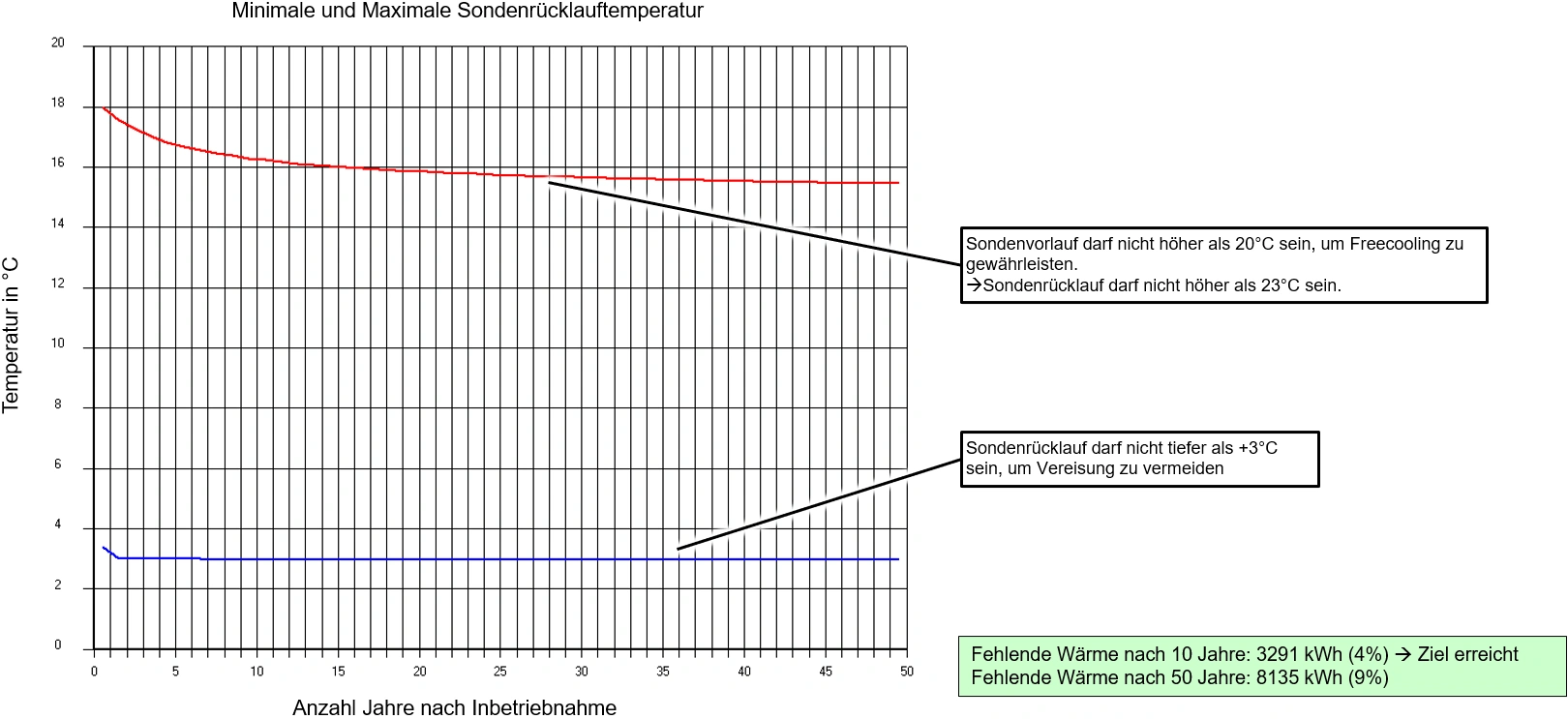

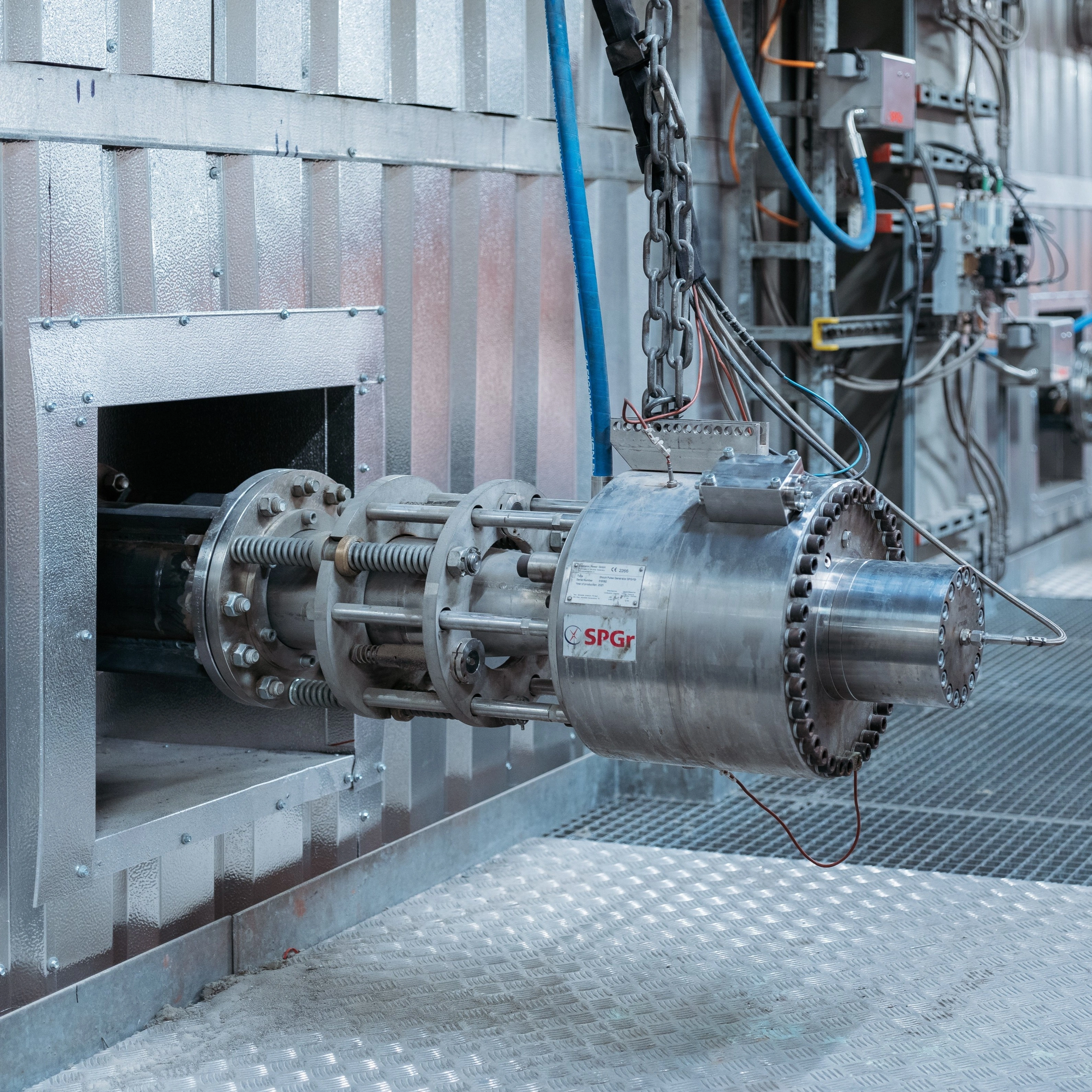

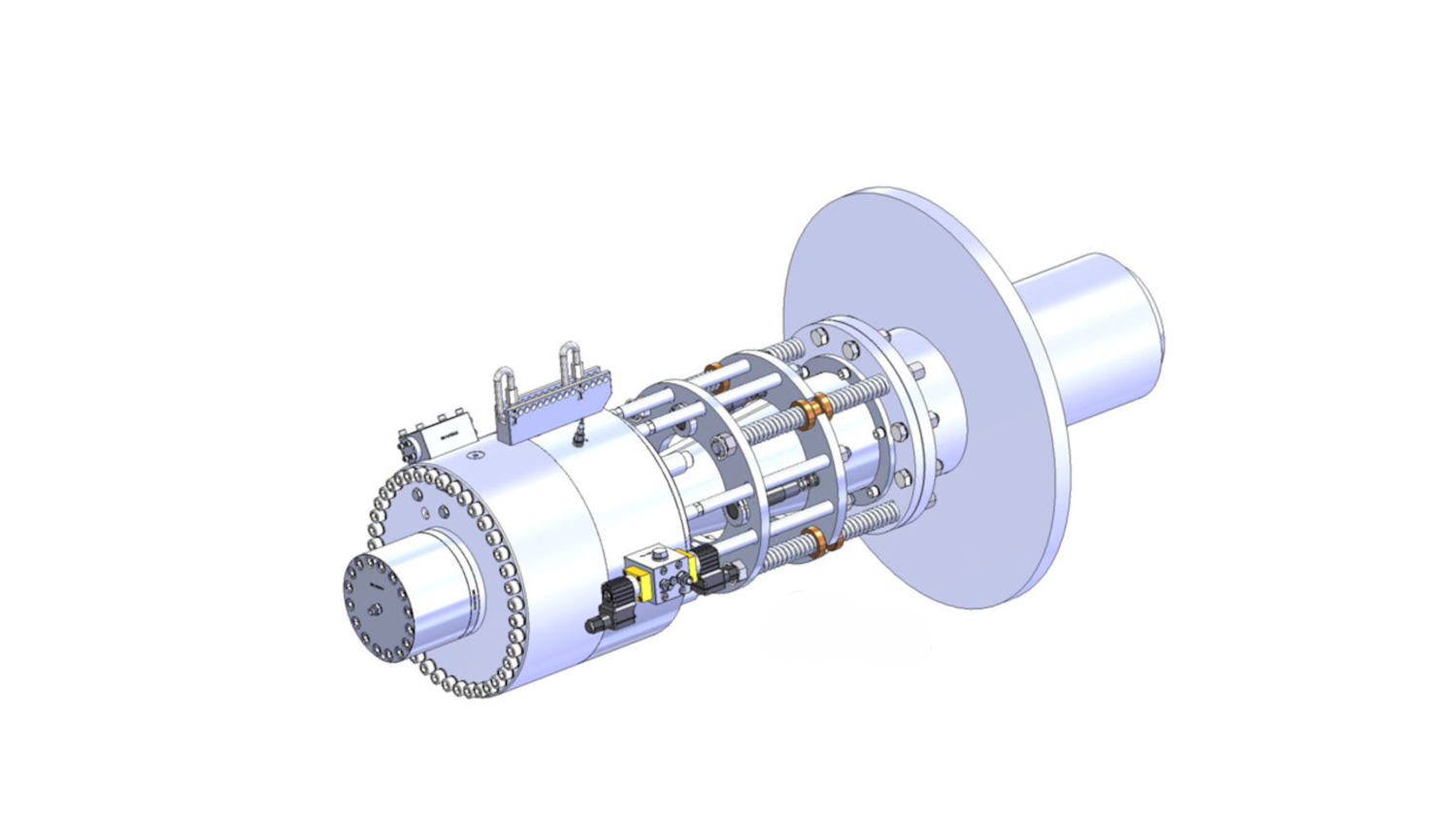

At the heart of the technology is the patented Shock Pulse technology, which enables highly efficient and non-invasive boiler cleaning during ongoing operation. Based on this technology, the Shock Pulse Generator (SPG) was developed – an automated boiler cleaning solution that generates targeted pressure waves to reliably remove deposits from heat exchanger surfaces.

By means of a controlled combustion of a precisely balanced gas-air mixture, strong pulses are created that ensure effective cleaning without mechanical contact. The entire process is fully automated and designed for continuous 24/7 operation. The result: optimised plant performance, extended operating cycles, and significantly reduced maintenance costs.

Key Figures

- Over 1,300 Shock Pulse Generators have been commissioned worldwide since 2009.

- Explosion Power has been working successfully with Helbling since 2018.

- Shock Pulse Generators enable continuous boiler cleaning.

- Pressure waves enhance the cleaning effect and reduce flue gas temperatures.

- Improved boiler efficiency increases operational performance.

- High safety standards – the boiler remains closed during operation.

- Longer operating intervals significantly increase plant availability.

- Heating surfaces can be reduced without lowering steam output.

- Smaller space requirements save on construction volume and improve planning.

- Fewer cleaning devices lower investment costs.

- Modular design allows for fast and simple installation.

Our Contribution

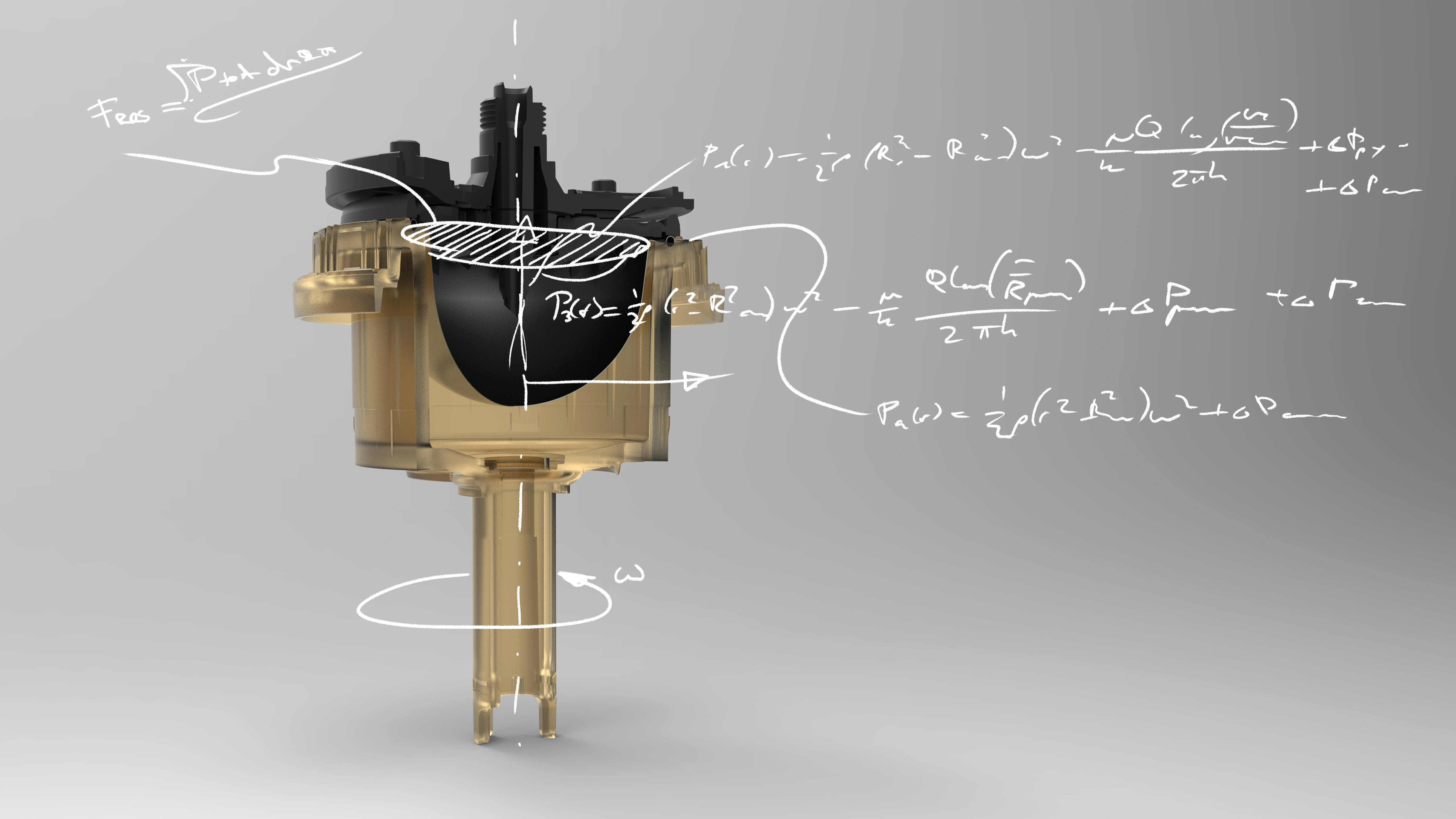

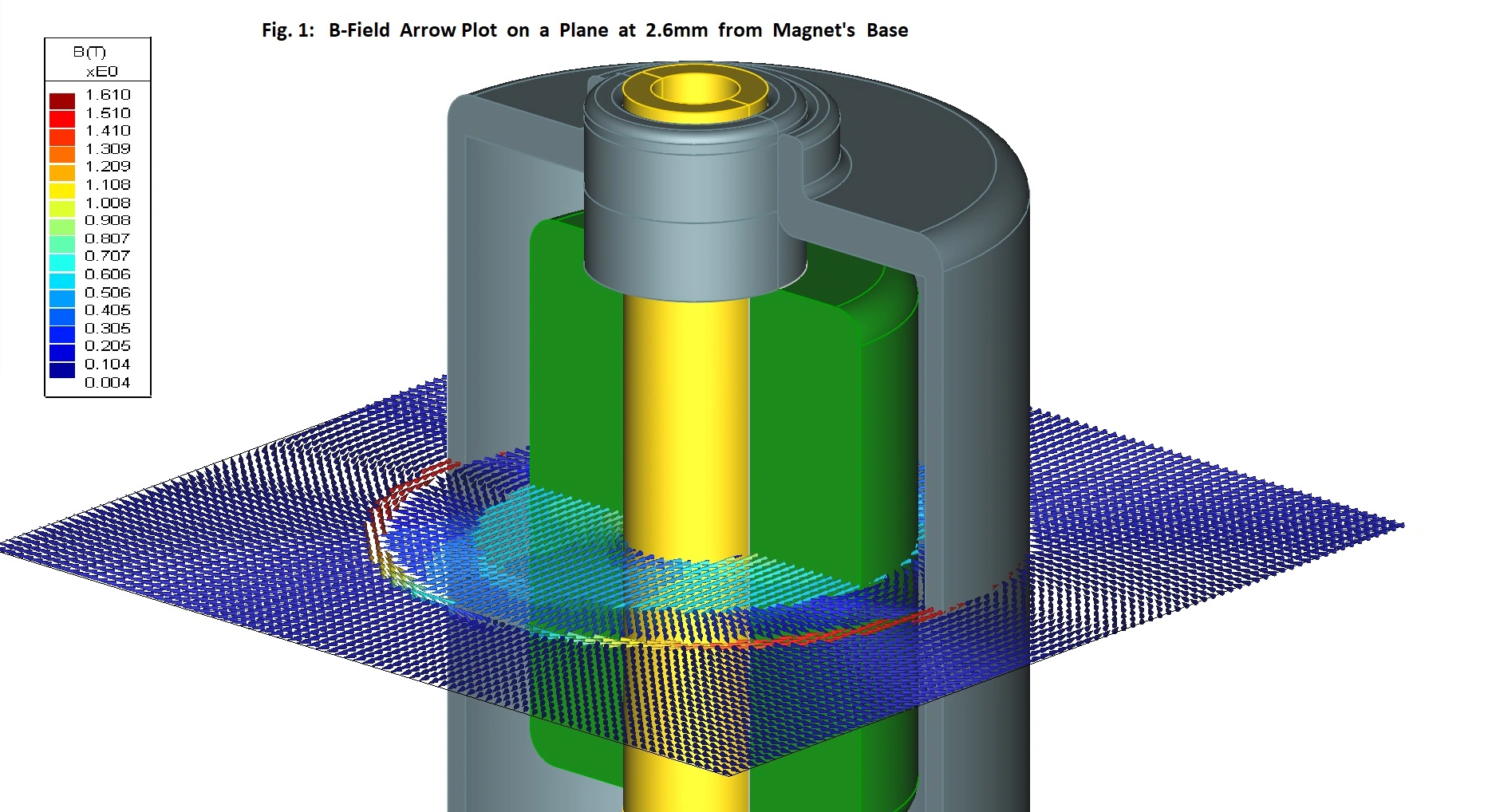

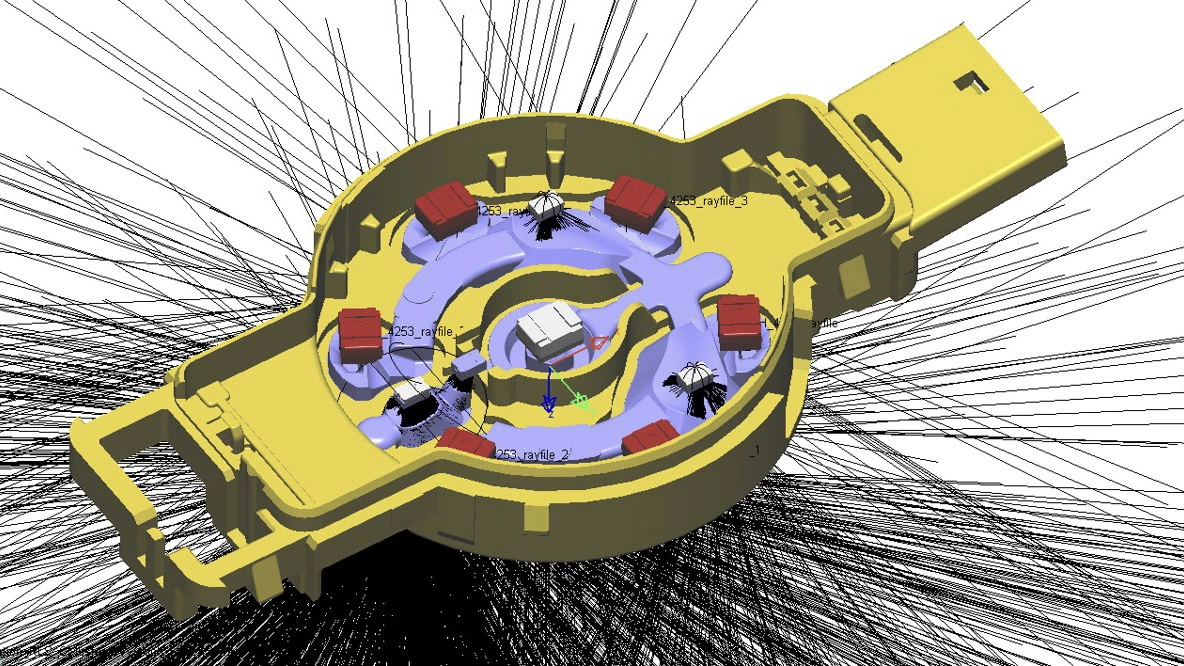

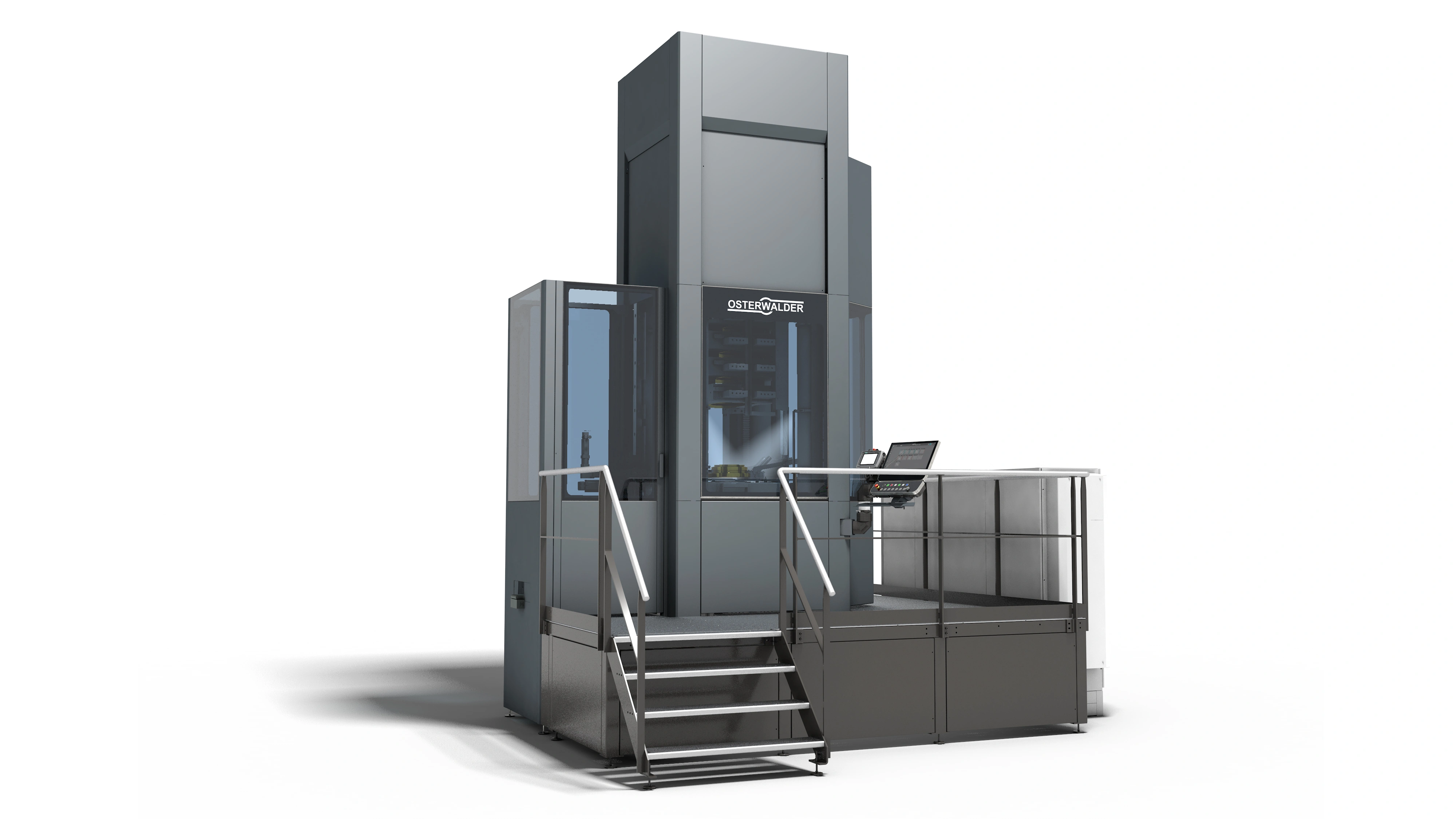

- Development of a new generation of SPG with redesigned combustion process

- Theoretical considerations and conceptual work

- Design of the overall system and main components

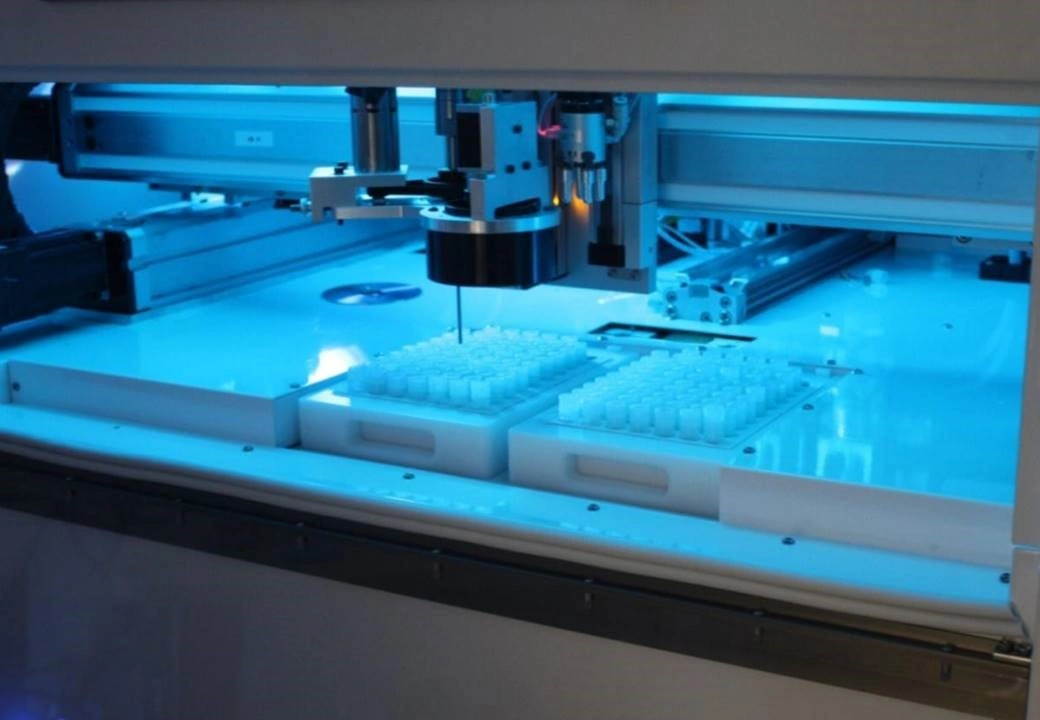

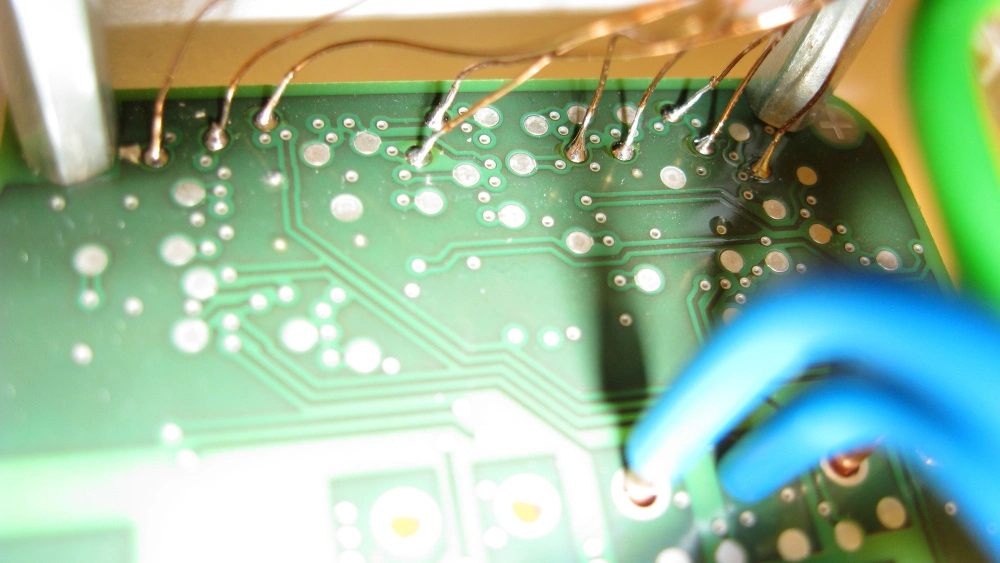

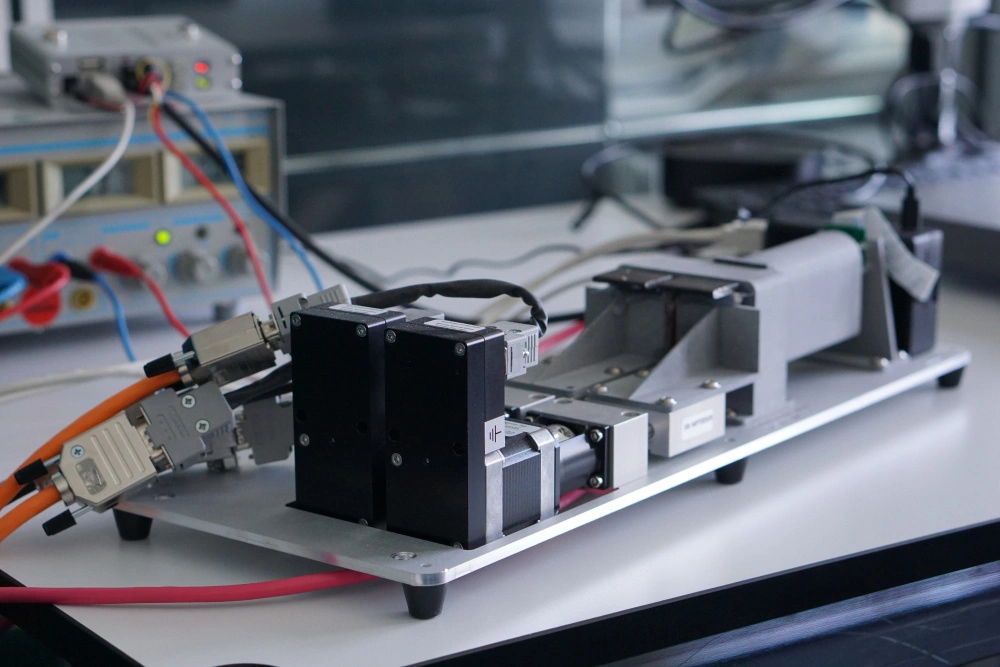

- Construction of a test bench for functional tests

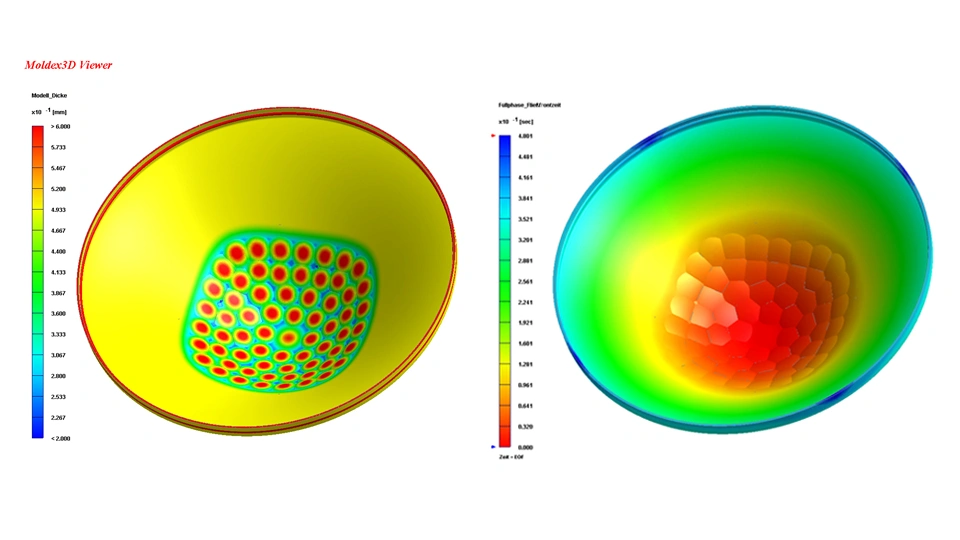

- System simulations to accompany functional tests

- Further development based on synthesis of tests and system simulations

- Export of a digital twin for control development

- Strength verification for the notified body

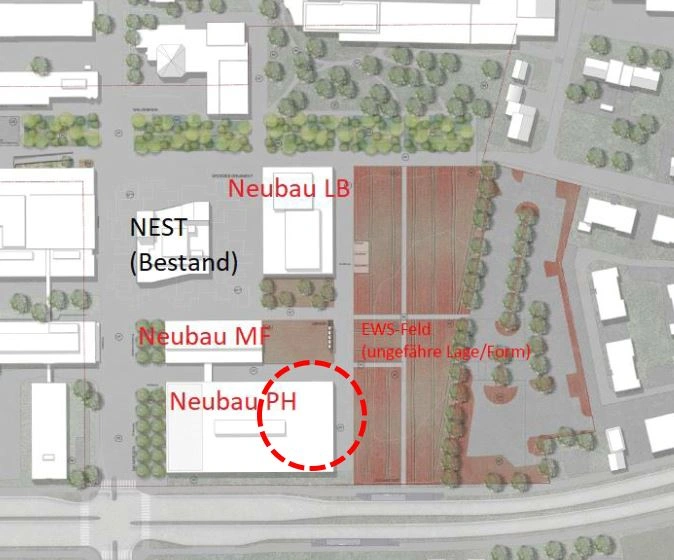

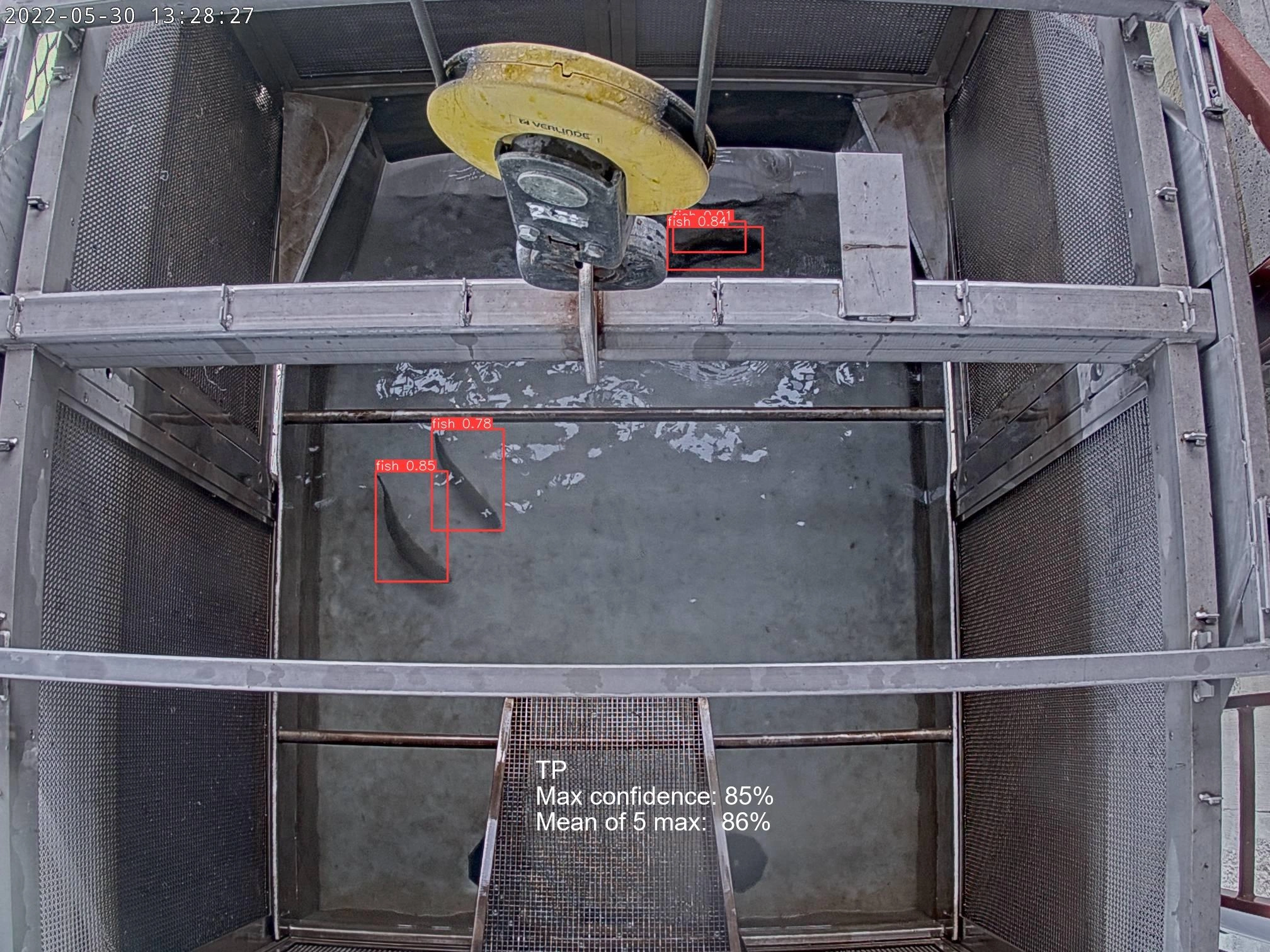

- Open field measurements of the pressure wave for performance assessment

- Conducting a three-week test on a plant

- Simulation and test bench-driven development

- Tolerance analyses· Design support· Product maintenance

- Creation of illustrations for sales and project management

- Support with internal restructuring in the logistics department

Click to play video.

Find out more about Explosion Power: www.explosionpower.ch

Outcome

The Shock Pulse Generator (SPG) reduces the operating and maintenance costs for plant operators through an efficient, automated, and equipment-friendly cleaning process. Its continuous operation significantly reduces manual cleaning requirements, extends service intervals, and increases plant availability. At the same time, the regular removal of deposits helps lower flue gas temperatures, sustainably improving the thermal efficiency of the boiler.

Cases

Internationales Unternehmen der Papierindustrie – Analyse des Dampfsystems

Industries:

Services:

Cases

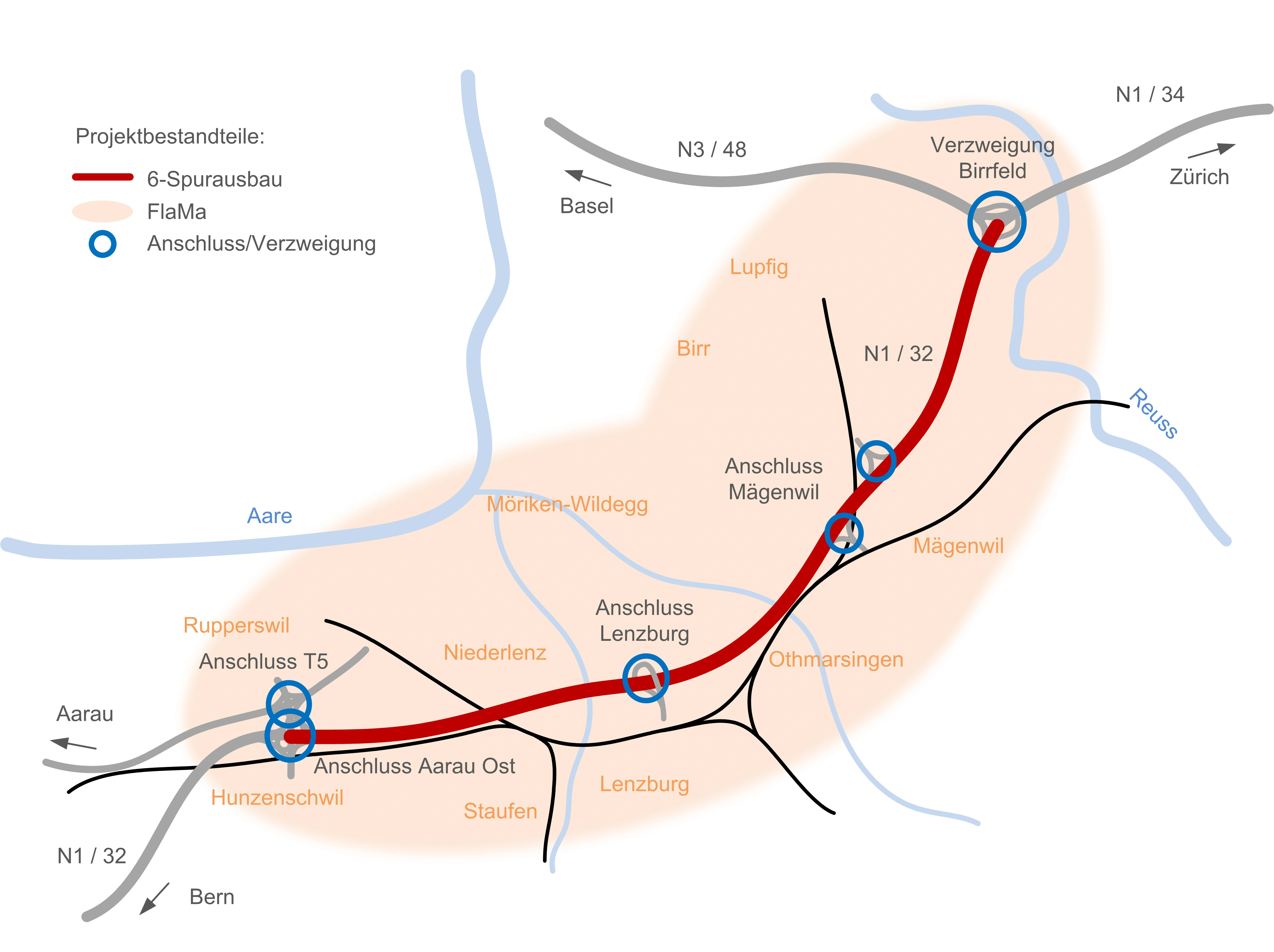

6-Streifenausbau Aarau Ost – Verzweigung Birrfeld – Bauherrenunterstützung

Industries:

Services: